Dodge NV5600 Transmission

Convert your Dodge NV5600 to an Allison

Transform Your Drive: Making the Switch to an Allison 1000PK Transmission

Configure your truckUpgrade your driving experience with a Dodge NV5600 to Allison 1000PK Transmission Conversion, the perfect solution for maximizing your vehicle’s performance, efficiency, and reliability. The Allison 1000PK, renowned for its seamless shifting, remarkable durability, and top-tier load-carrying capacity, stands as a gold standard in automatic transmissions. By converting from the Dodge NV5600, a manual six-speed, to the Allison 1000PK, you not only gain the ease and convenience of an automatic transmission but also benefit from enhanced fuel efficiency and towing capabilities that Allison is celebrated for. Whether you’re navigating rugged terrains, hauling heavy loads, or simply desiring a smoother ride, this conversion is your ticket to transforming your Dodge into a powerhouse of performance and reliability. Elevate your driving experience — make the switch to the Allison 1000PK today.

Overview of the NV5600 Transmission

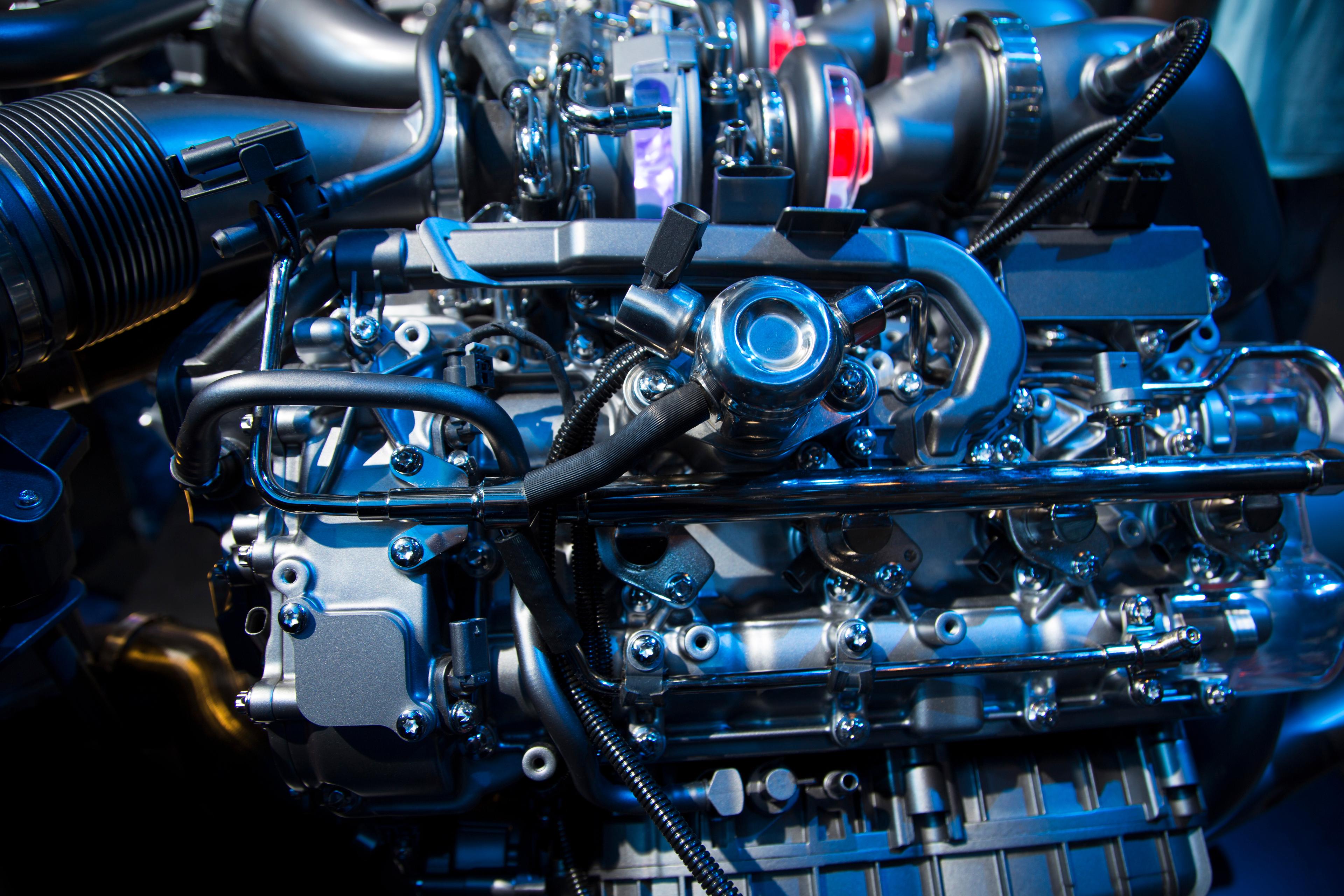

The NV5600 is a six-speed manual transmission designed and manufactured by New Venture Gear (NVG), a former joint venture between Chrysler and General Motors. Introduced in the late 1990s, the NV5600 quickly gained widespread acclaim among heavy-duty truck enthusiasts for its robust construction and exceptional torque capacity. Engineered primarily for use in Dodge Ram 2500 and 3500 series trucks equipped with the renowned Cummins turbodiesel engine, this transmission has proven itself to be remarkably reliable and capable of handling rigorous applications, particularly in the context of heavy towing and hauling duties.

Its fully synchronized gears, including a dual-cone synchronizer on 2nd and 3rd gears, allow for smoother and more precise shifting, making it a popular choice for those who prefer the control that comes with a manual transmission. Constructed with a cast iron case and an aluminum shift cover, the NV5600 is built to endure — its design speaks to both durability and functionality. With a respectable gear ratio spread, it allows for comfortable and fuel-efficient highway cruising, while still offering enough low-end grunt for substantial towing and payload capacities.

However, as manual transmissions have become increasingly rare in modern trucks, the NV5600 represents a bygone era to some extent. It appeals to a specific kind of driver — one who values the tactile engagement and direct control that a manual transmission provides. For those who are willing to forego the convenience of an automatic for a more hands-on and connected driving experience, the NV5600 remains a cherished and sought-after option.

NV5600 Features

The NV5600 transmission is a powerhouse designed for heavy-duty trucks, most notably the Dodge Ram 2500 and 3500 series. It is celebrated for its durability and its ability to handle high torque applications, a primary reason why it was often paired with the Cummins turbodiesel engines in Dodge trucks. Here are some key features that make the NV5600 stand out:

- High Torque Capacity: The NV5600 offers a six-speed manual shifting experience, allowing drivers to have precise control over their vehicle's performance and fuel economy.

- High Torque Capacity: Engineered for heavy-duty applications, the NV5600 is designed to handle high levels of torque, making it ideal for towing and hauling heavy loads.

- Fully Synchronized Gears: All gears, including reverse, are synchronized in the NV5600, which allows for smoother and quicker shifts. This transmission features a dual-cone synchronizer on 2nd and 3rd gears for enhanced shifting precision.

- Durable Construction: The NV5600 is built to last, with a rugged cast iron case and an aluminum shift cover. Its construction is robust and designed to withstand the rigors of heavy-duty truck use.

- Wide Gear Ratio Spread: The NV5600 has a broad range of gear ratios, from a deep 5.63:1 first gear for heavy hauling to a 0.73:1 overdrive sixth gear that allows for fuel-efficient highway cruising.

- Integrated Oil Cooler Ports: To help maintain optimal operating temperatures and prolong the life of the transmission, the NV5600 features ports for an external oil cooler.

- PTO (Power Take Off) Capability: The NV5600 was available with an option for PTO, which allows for the transmission to power auxiliary equipment—a crucial feature for many commercial applications.

- Clutch Engagement: The NV5600 typically employs a 13-inch single-disc clutch, which provides strong and reliable engagement, essential for heavy-duty and high-torque applications.

- Direct and Responsive Shifting: As a manual transmission, the NV5600 offers a level of driver engagement that can’t be matched by automatic counterparts. It provides a tactile and direct connection between the driver and the vehicle.

- Aftermarket Support: Due to its popularity among enthusiasts and its longstanding presence in the market, there is robust aftermarket support for the NV5600. This includes a wide variety of parts and upgrade options that allow owners to customize and further improve their transmission’s performance.

In summary, the NV5600 is a robust, reliable, and versatile manual transmission designed to handle the rigorous demands of heavy-duty truck applications. Its features are tailored to offer drivers precise control, substantial towing capacity, and enduring performance under a variety of conditions.

NV5600 Common Issues and Signs of Failures

While the NV5600 transmission is revered for its durability and heavy-duty performance, like any mechanical component, it can have its share of issues. Here are some common problems associated with the NV5600 transmission, along with signs that it might be failing:

- Synchro Wear: Over time, the synchronizers, which help the gears in the transmission mesh smoothly, can wear down. This can lead to hard shifting, grinding noises when changing gears, and potentially gears popping out of place.

- Clutch Problems: Due to the high torque applications this transmission is often subjected to, the clutch can wear out or fail, resulting in difficulty shifting, complete loss of drive, or a soft or spongy clutch pedal.

- Input Shaft Issues: Under heavy loads, the input shaft can suffer from extreme stress. Signs of a failing input shaft might include noisy operation in certain gears or complete loss of drive.

- Bearing Failures: The NV5600's bearings, particularly the input and output shaft bearings, can wear out over time. This typically results in noisy operation, including whining or grinding sounds, especially when the clutch is engaged or disengaged.

- Oil Contamination and Lubrication Issues: Proper lubrication is critical for the NV5600. If incorrect or contaminated fluid is used, it can lead to accelerated wear and potential failure. Signs of this might include noisy operation, hard shifting, and excessive heat.

- Fifth Gear Nut Backing Off: A known issue with some NV5600 transmissions is the fifth gear nut loosening and backing off. This can lead to fifth gear becoming inoperative and may cause additional damage if not addressed promptly.

- Shift Fork Wear: The shift forks, which are used to engage the various gears, can wear or break. This typically results in difficulty shifting into or staying in certain gears.

- Case Flex and Cracking: Under extremely heavy loads, the case of the NV5600 can flex, which may lead to misalignment of internal components and potential cracking of the case itself. This is generally accompanied by leaking fluid and noisy operation.

- Overheating : Heavy towing and hauling can lead to excessive heat, which is a common killer of transmissions. Overheating can lead to warped components, fluid breakdown, and eventual transmission failure.

- Gears or Shaft Breakage: Under extreme stress, particularly in situations of shock loading (sudden application of high torque), the gears or shafts inside the NV5600 may break. This will result in a sudden loss of drive and likely loud noises from the transmission.

It is worth noting that regular maintenance, including proper lubrication with the correct transmission fluid and timely replacement of worn components, can significantly extend the life of an NV5600 transmission and prevent many of these issues.

When experiencing any of these symptoms, it is advisable to consult with a professional mechanic or transmission specialist to diagnose and address the problem before it leads to a complete transmission failure.

Rebuild, Replace, Converting to an Allison

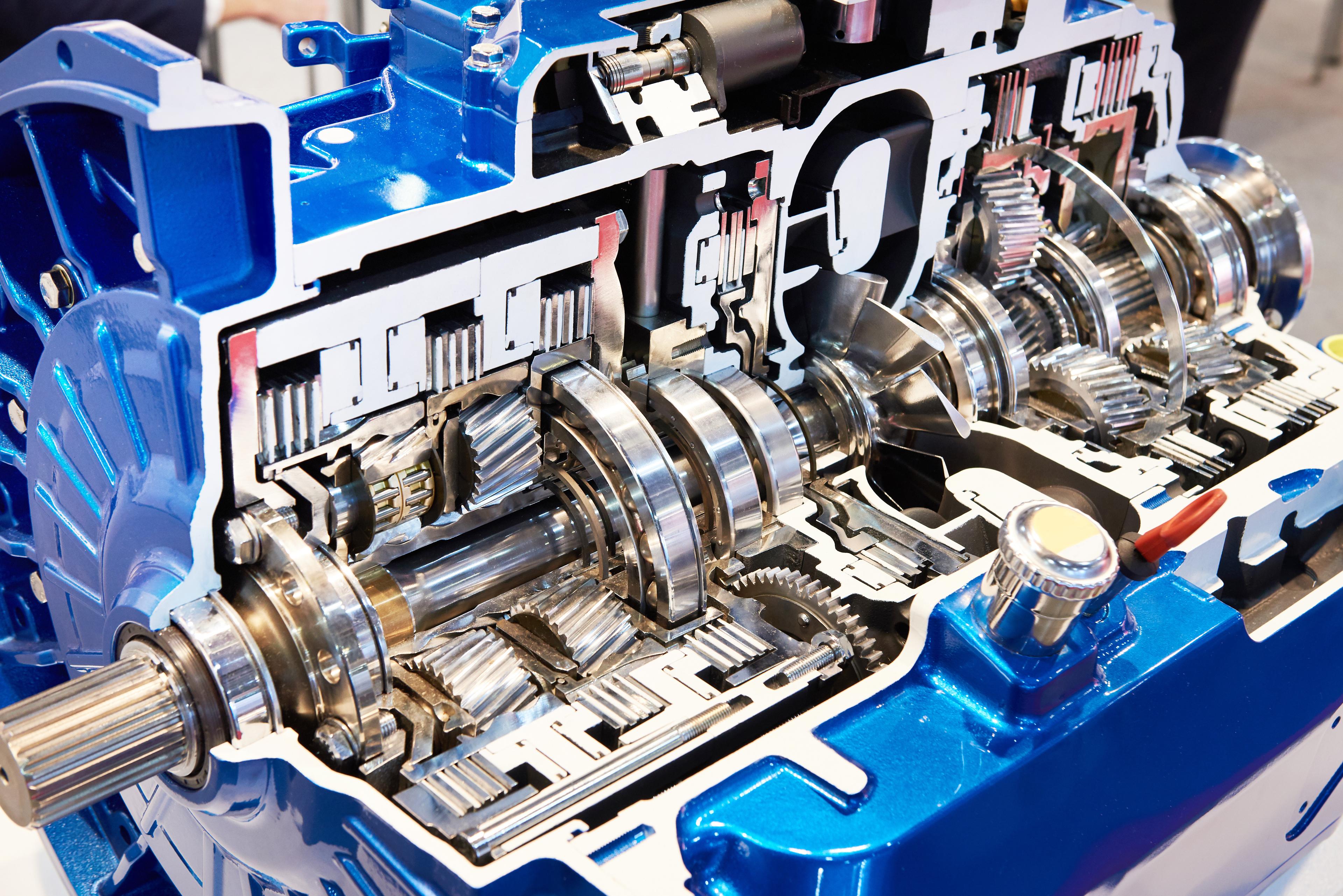

Converting from a Dodge NV5600 manual transmission to an Allison 1000PK automatic transmission can bring several benefits, depending on the specific needs and use of the vehicle. Here are some notable advantages of making such a conversion

The Allison 1000PK is an automatic transmission, which makes the vehicle easier to drive, especially in heavy traffic conditions where a manual transmission can be cumbersome.

The Allison 1000PK is known for its exceptional towing capabilities. It is often chosen for heavy-duty applications due to its strength and reliability when pulling heavy loads.

The Allison 1000 series transmissions are renowned for their durability and can have a longer lifespan under heavy-duty use compared to some other transmissions, including the NV5600.

The Allison 1000PK provides smooth and precise shifts, which can contribute to a more comfortable and enjoyable driving experience.

Some drivers may experience improved fuel efficiency with an automatic transmission like the Allison 1000PK due to its optimized shifting patterns.

The Allison 1000PK often features more advanced technology, including adaptive shift controls that adjust to driving conditions, resulting in optimized performance.

Automatic transmissions can help reduce wear on associated drivetrain components, as the computer-controlled shifts can be more consistent and less stressful on the equipment than manual shifting.

For some buyers, a vehicle with a well-regarded automatic transmission like the Allison 1000PK may have higher resale value due to its ease of use and strong reputation for reliability.

The Allison 1000PK can be a great fit for a variety of applications, from daily driving to heavy-duty towing, making the vehicle more versatile.

For long-haul or frequent drivers, an automatic transmission can result in less fatigue as it requires less constant attention and shifting effort compared to a manual transmission.

The Allison 1000PK has been used in a variety of setups, potentially offering more flexibility for engine swaps or other modifications.

We provide everything you will need to get the swap done right

- Kit Includes

Allison 1000PK Transmission

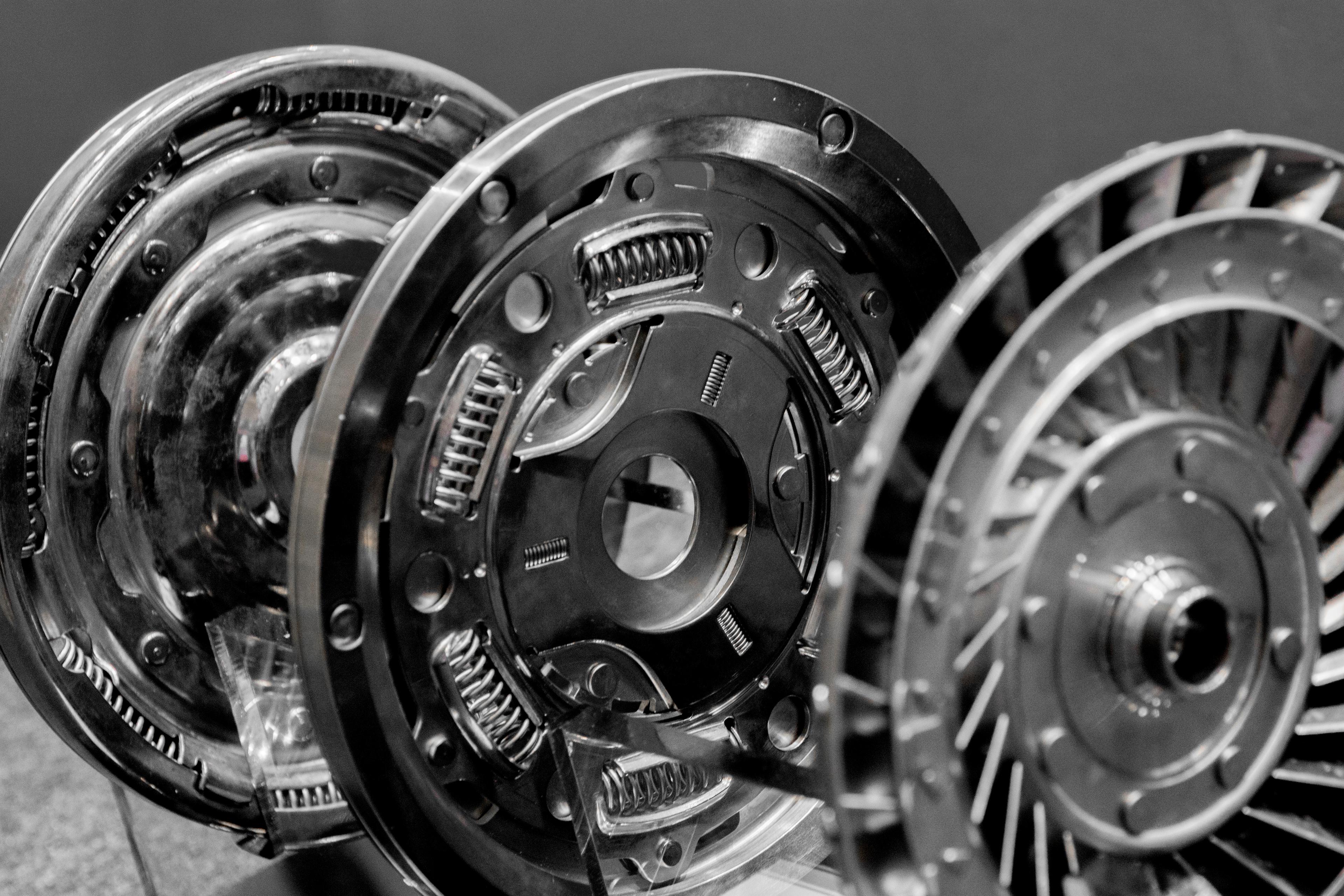

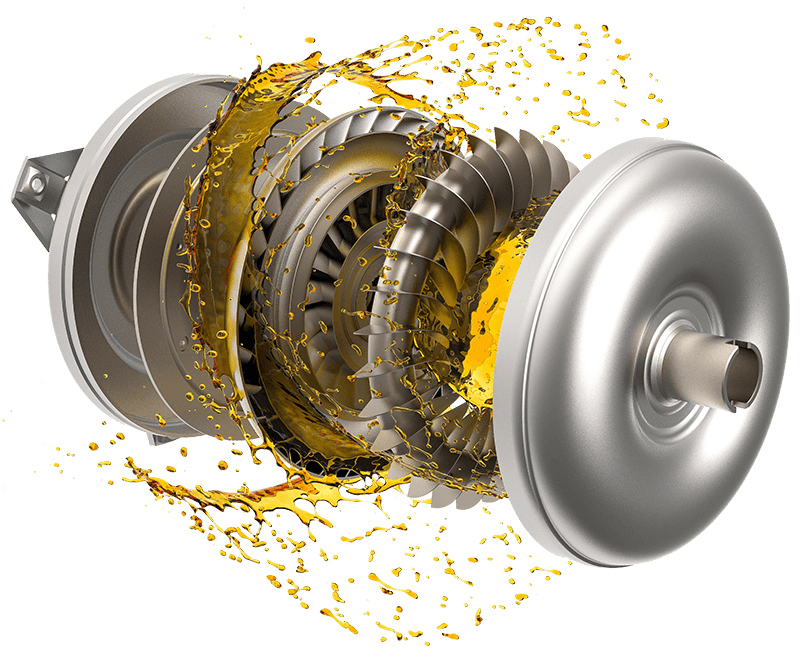

Torque Converter to fit your needs

Wiring Harness

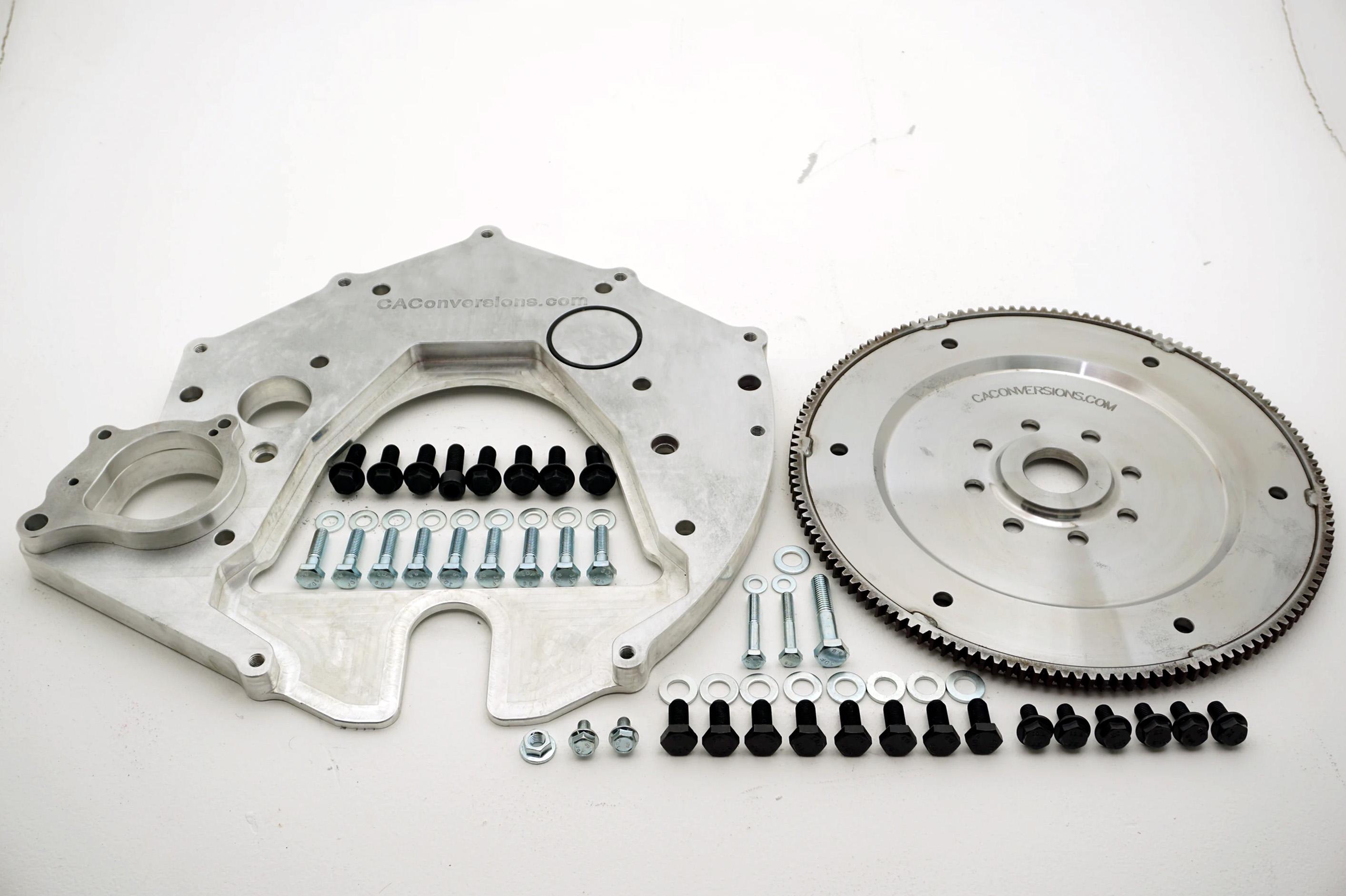

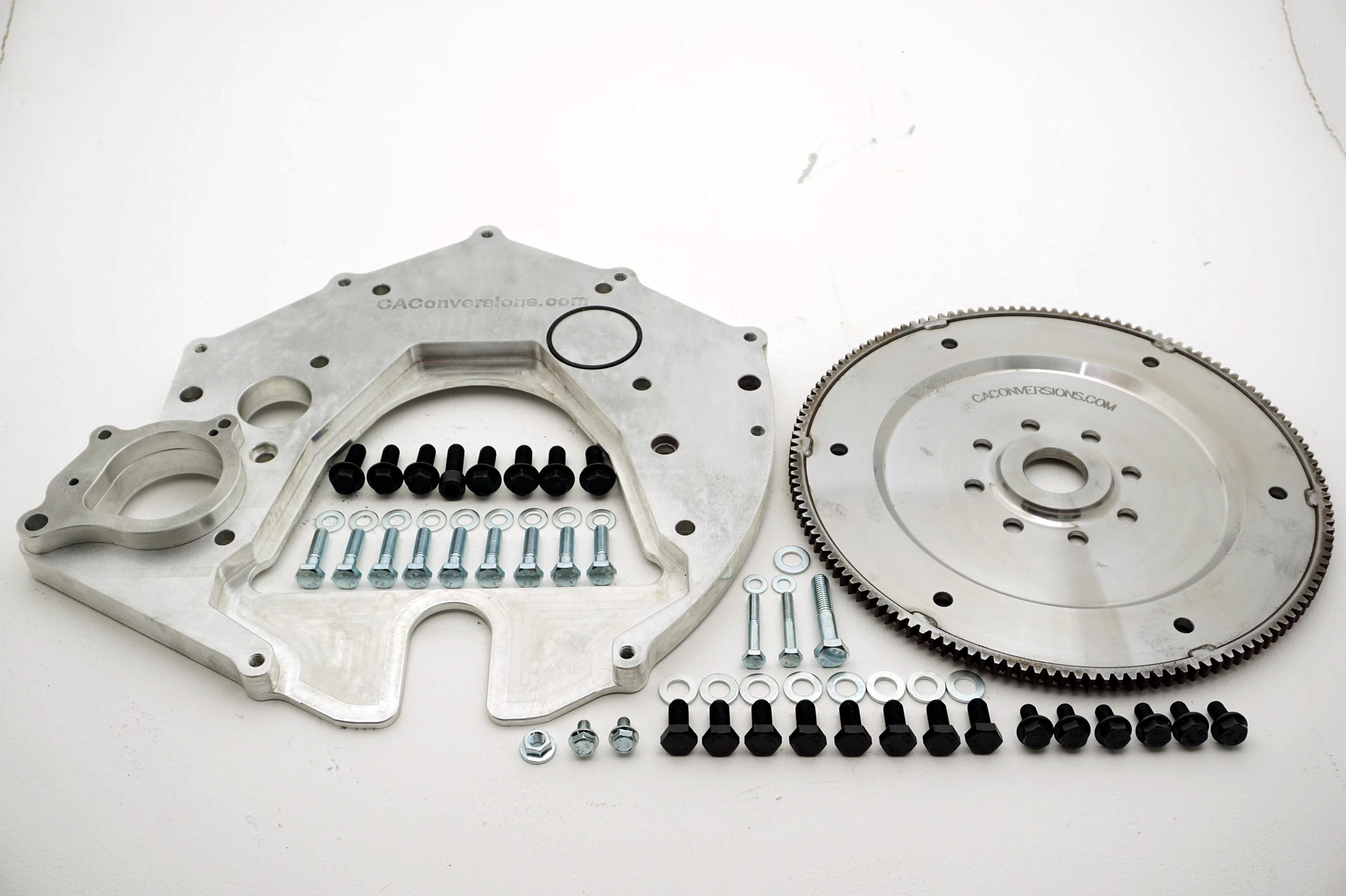

Flex Plate Adapter

Transfer Case Adapter, Couplers, and Tone Rings

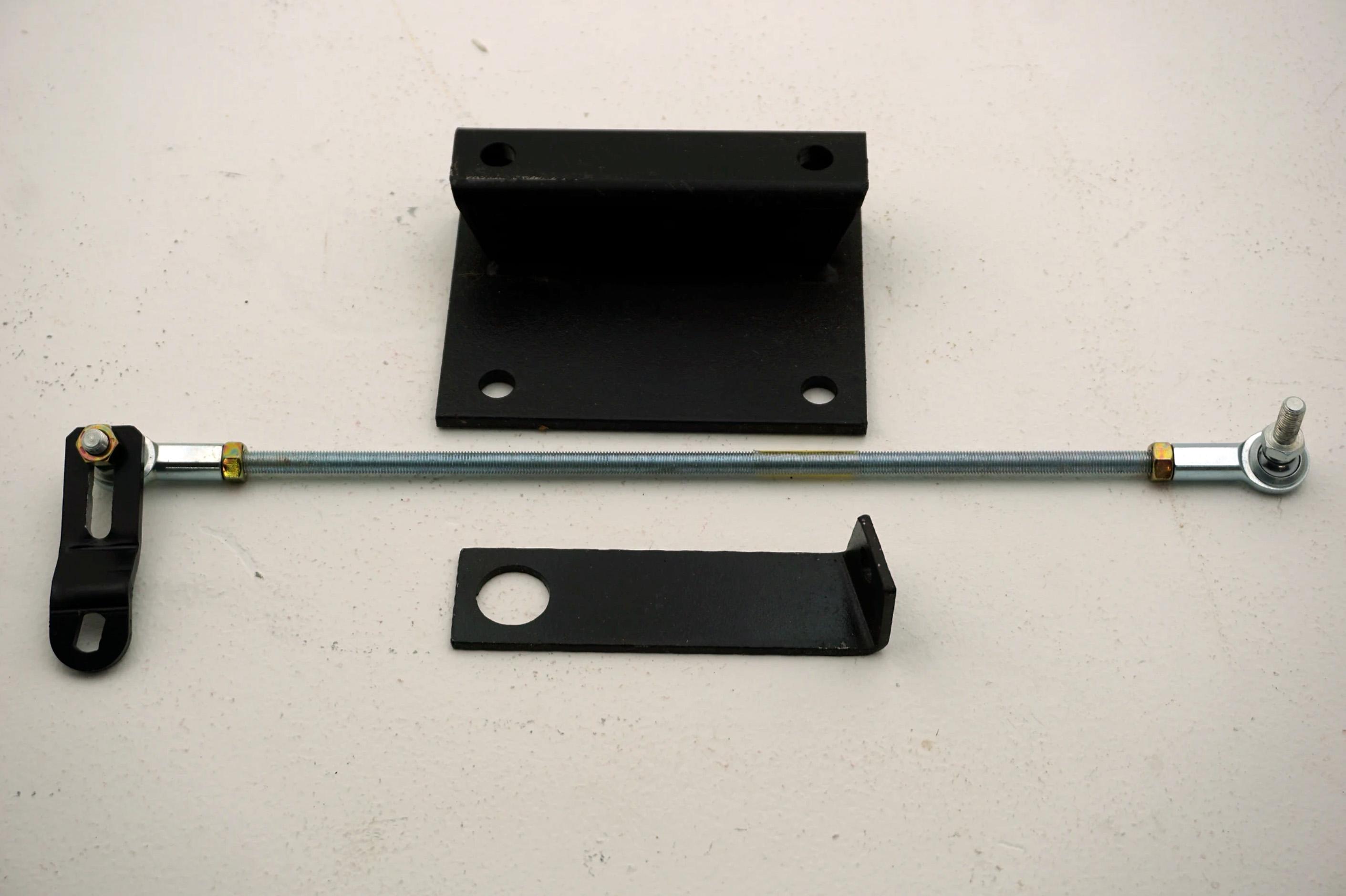

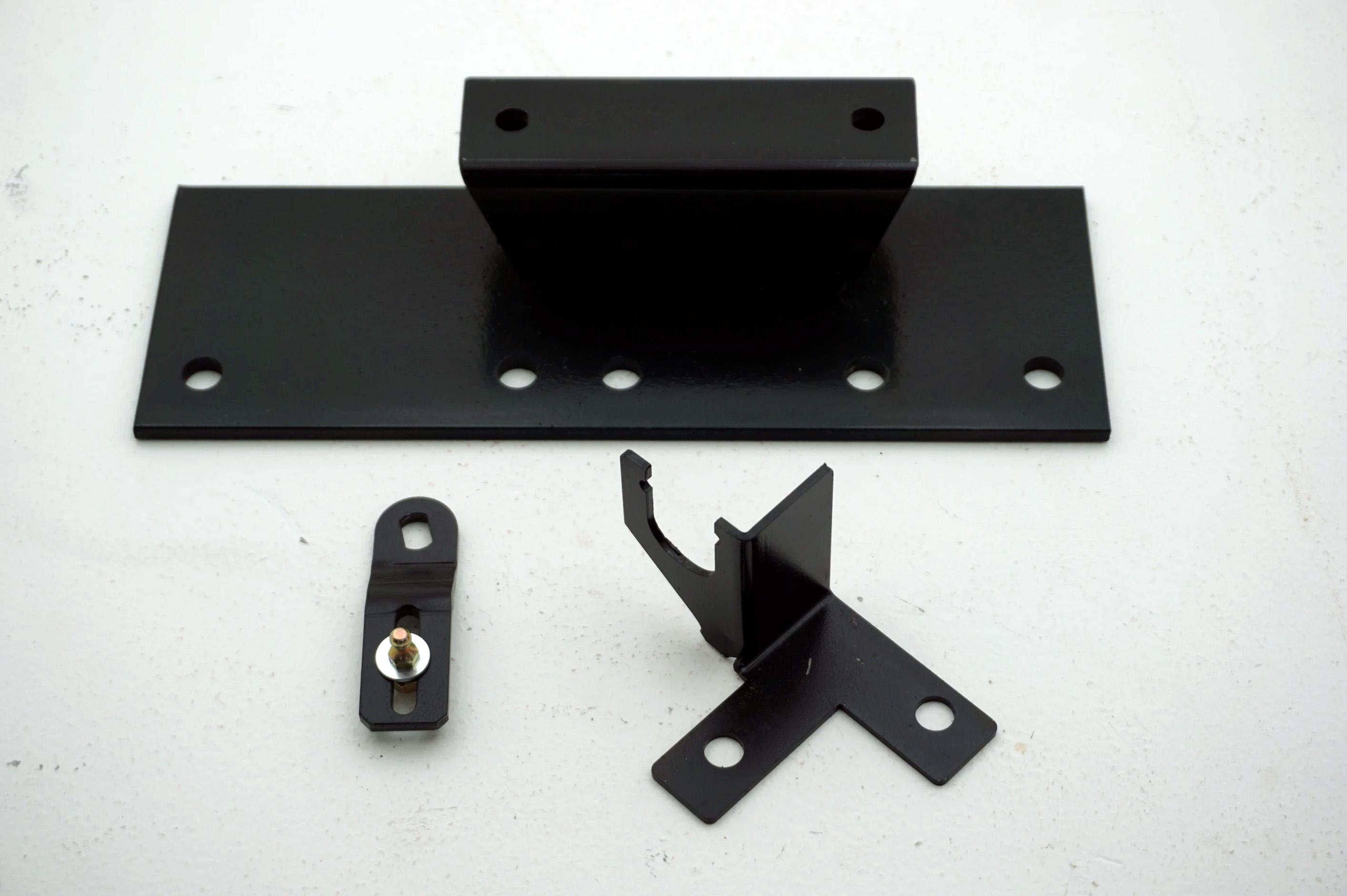

Mounting Kit and Shift Linkage

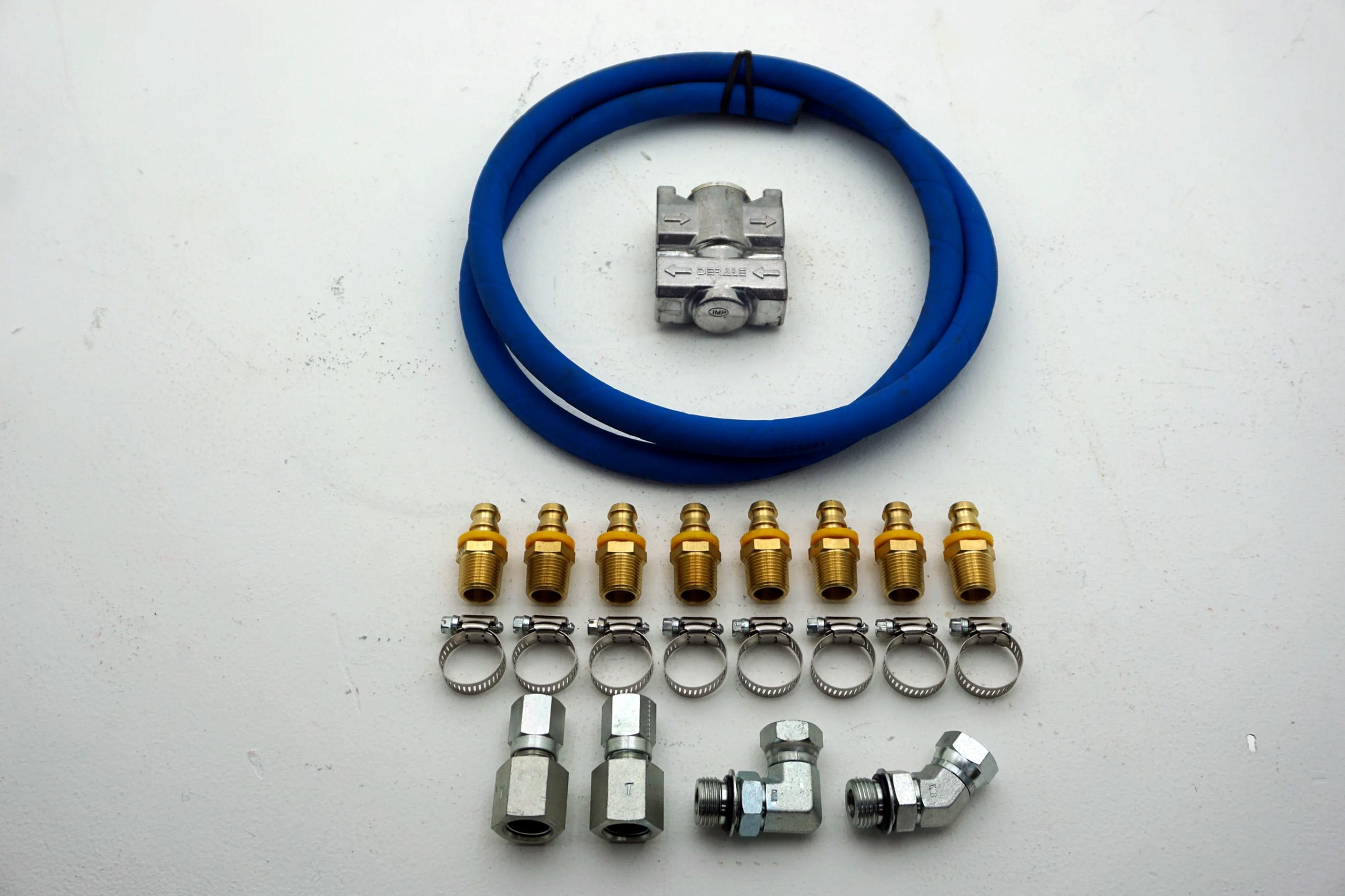

Cooling Kit

CAC Digital Display

Allison Total Control Module (TCM)

CAC Total Control Module (TCM)

NV5600 Allison Conversion Kits

How to determine the Right Torque Converter

Maximizing Performance: Using Tire Diameter and Gear Ratio Calculations to Choose the Ideal Torque Converter

FAQ'S

What are the benefits of converting my Dodge Ram's current transmission to an Allison?

Converting your Dodge Ram's transmission to an Allison can result in numerous benefits including improved durability, enhanced towing capability, increased fuel efficiency, and smoother gear shifts, thus optimizing your vehicle's performance.

Is an Allison conversion compatible with all Dodge Ram models?

Most Dodge Ram models can benefit from an Allison transmission conversion, but it's advisable to consult with a specialist to ensure compatibility with your specific model.

Can I use my existing Dodge Ram transfer case with an Allison conversion?

Yes, with the right adapters, your existing Dodge Ram transfer case can be utilized in an Allison conversion.

Which Allison transmissions are best suited for Dodge Ram vehicles?

The Allison 1000 series is a popular choice for Dodge Ram vehicles due to its reliability and performance, but the best option depends on your particular needs and vehicle model.

What is the process for converting my Dodge Ram's transmission to an Allison?

The conversion process involves removing your Dodge Ram's current transmission, fitting the Allison transmission with the necessary adapters, and installing it. The wiring harness, TCM, and other components are also adjusted accordingly.

Will my Dodge Ram's performance and fuel economy improve with an Allison transmission conversion?

Yes, an Allison transmission is designed to provide smoother shifts, increased durability, and better fuel efficiency, all of which contribute to improved vehicle performance.

What specific components come with the Allison conversion kit for Dodge Ram vehicles?

An Allison conversion kit typically includes components such as the transmission (if chosen), TCM, torque converter, wiring harness, adapters, and other necessary parts for the conversion.

Can I provide my own Allison transmission for the conversion, or can it be included in the kit?

You have the option to either provide your own Allison transmission or include it with your conversion kit purchase.

Can I perform the Allison transmission conversion myself, or do I need a professional?

While it's possible for experienced individuals to do the conversion, it's generally recommended to hire a professional to ensure the job is done correctly and safely.

How long does a typical Allison conversion take for a Dodge Ram?

The conversion time can vary based on the vehicle and the specific conversion kit. On average, it might take a few days to complete.

Will converting my Dodge Ram's transmission to an Allison affect my warranty?

An Allison conversion could affect your vehicle's warranty depending on the specific terms of your warranty agreement. We recommend checking with your warranty provider before proceeding with the conversion.

What should I do if I encounter issues after converting my Dodge Ram's transmission to an Allison?

If you face any problems after the conversion, it's best to contact your conversion specialist for troubleshooting assistance or potential service needs.

Can I use an Allison transmission from a different vehicle (like a Chevrolet/GM) for my Dodge Ram conversion?

Yes, an Allison transmission from another vehicle can be used, provided it's compatible with your Dodge Ram model. Ensure to consult with your conversion specialist before proceeding.

Do you offer rebuilding services for Allison transmissions?

Yes, we do offer rebuilding services for Allison transmissions, ensuring your transmission is operating at peak performance.

What is the cost range for an Allison transmission conversion for Dodge Ram vehicles?

The cost can vary significantly depending on the specific Allison model, whether you're providing the transmission or purchasing it as part of the kit, and any additional services required. Please contact us directly for a more precise estimate.

Financing Available

Financing is available, so that you can get on the road faster