Ford ZF S5-47 Transmission

Convert your Ford ZF S5-47 to an Allison

Transform Your Drive: Making the Switch to an Allison 1000PK Transmission

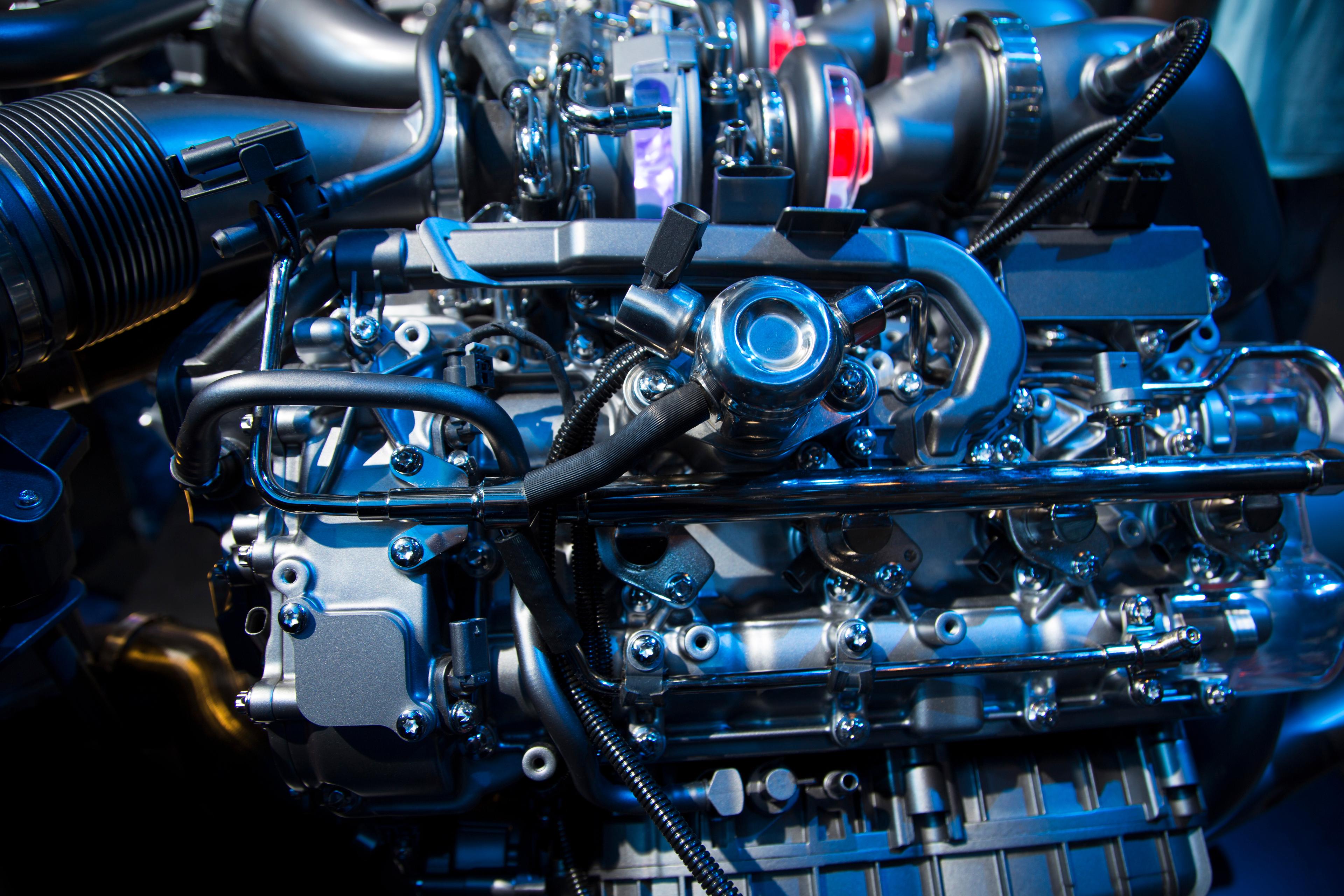

Configure your truckUnleash the true potential of your Ford with a ZF S5-47 to Allison 1000PK transmission conversion. This upgrade replaces the venerable ZF 5-speed manual, renowned for its ruggedness but often seen as the limiting factor in power and torque capabilities, with the modern, silky-smooth, and heavy-duty Allison 1000PK 6-speed automatic. Not only does this conversion allow your truck to handle more power while providing exceptional towing capability and reliability, but it also introduces a new level of driving comfort and efficiency, especially for those long-haul journeys. Don’t just drive—experience the road like never before with the unparalleled performance and luxury that the Allison 1000PK transmission brings to your Ford.

Overview of the ZF S5-47 Transmission

The ZF S5-47 is a renowned manual transmission designed and manufactured by ZF Friedrichshafen AG, a leading global technology company. Introduced in the 1990s, this five-speed manual transmission has become a trusted choice for Ford truck owners, known for its remarkable durability and high torque capacity. Specifically engineered for Ford trucks, including the F-250 and F-350 models, the S5-47 is frequently paired with Power Stroke diesel engines, forming a resilient and dependable powertrain combination. With its ability to endure harsh and demanding usage conditions, the S5-47 has solidified its place as a reliable solution for heavy towing and rigorous work tasks.

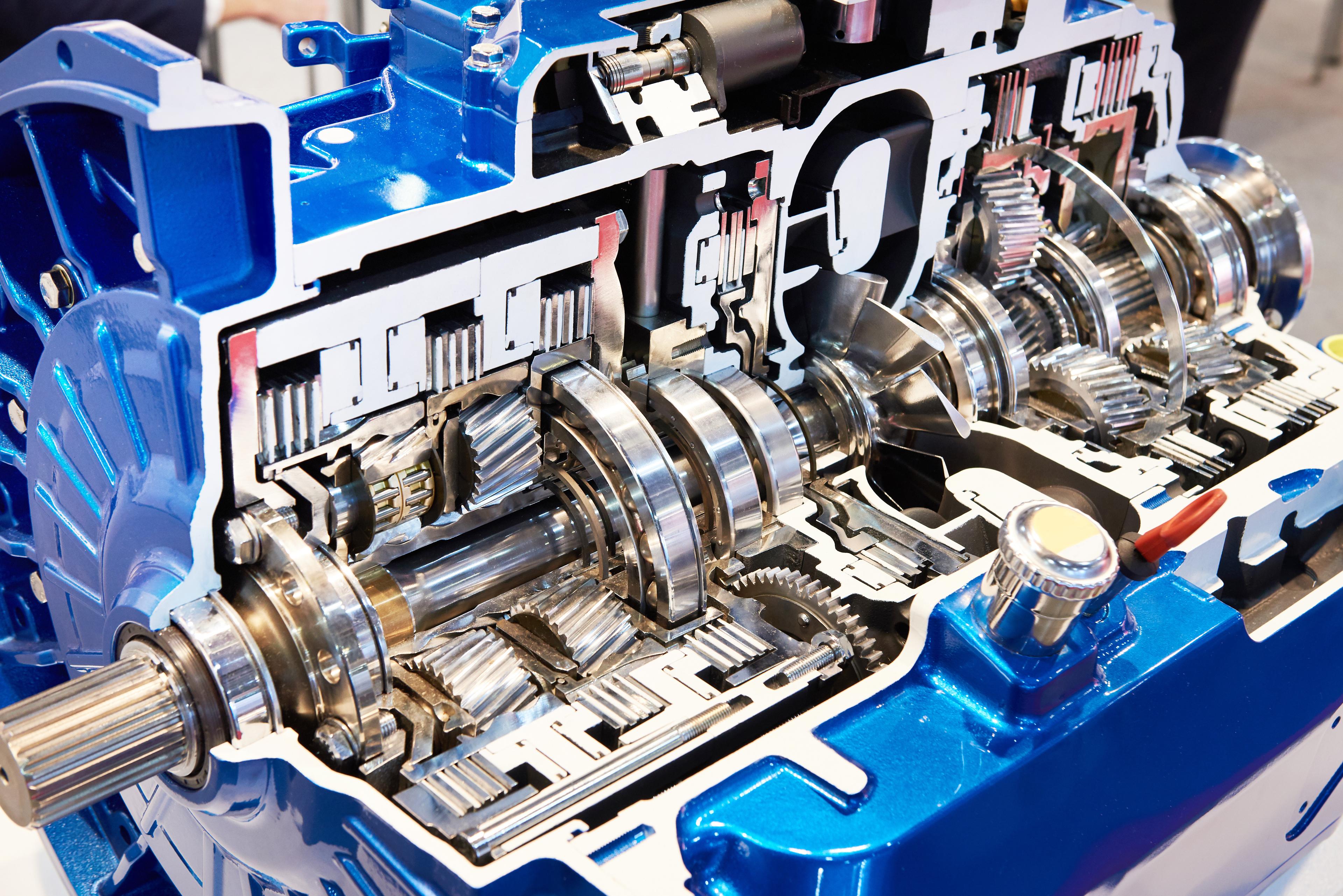

Featuring a fully synchronized gear set and a robust cast iron case, the S5-47 is constructed to deliver smooth and precise shifting that enhances both performance and driver control. Its well-engineered components and extensive use of tapered roller bearings are testament to its longevity and functionality. The transmission is designed with a range of gear ratios, ensuring it is proficient in towing heavy payloads while maintaining a comfortable and fuel-efficient cruising speed on the highway.

However, as automotive industry trends have shifted towards more gears and increasingly sophisticated automatic transmissions, the S5-47, while dependable, represents a past era of technology. It appeals to a certain type of driver—those who value the direct control and unambiguous nature of a classic, solid manual transmission. For these individuals, the S5-47 remains a cherished and reliable choice.

S5-47 Features

The S5-47 transmission is a stalwart designed for demanding Ford truck applications. Distinguished by its robustness and high torque capacity, here are some key features that make the S5-47 stand out:

- High Torque Capacity: Designed for heavy-duty applications, the S5-47 is constructed to handle elevated levels of torque, making it perfect for towing and hauling substantial loads.

- Fully Synchronized Gears: The S5-47 features fully synchronized gears, ensuring smooth and precise shifting under various operating conditions.

- Durable Construction: With its rugged cast iron case and hard-wearing internal components, the S5-47 is designed to endure the stringent demands of heavy-duty truck use.

- Wide Gear Ratio Spread: The S5-47 offers a diverse range of gear ratios, enabling robust towing capacity and fuel-efficient highway travel.

- Adaptable to Aftermarket Upgrades: Its well-established reputation has led to a flourishing aftermarket for the S5-47, offering parts and upgrade options for enthusiasts seeking to further optimize the transmission’s performance.

In summary, the S5-47 is a rugged, reliable, and versatile manual transmission crafted to handle the intense demands of heavy-duty truck applications. Its features are designed to provide drivers with exceptional towing capacity and enduring performance across a broad spectrum of conditions.

S5-47 Common Issues and Signs of Failures

While the S5-47 transmission is celebrated for its strength and heavy-duty performance, like any mechanical component, it can have its issues. Here are some common problems associated with the S5-47 transmission, along with signs that it might be failing:

- Gear Synchronizer Wear: Over time, the synchronizers, which enable smooth gear changes, can wear out, leading to grinding or hard shifting.

- Bearing Failures: The bearings in the S5-47 may fail due to heavy loads or insufficient lubrication, resulting in noise and potential damage.

- Input Shaft Wear: Heavy towing can put stress on the input shaft, leading to wear and potential failure.

- Seal and Gasket Leaks: Over time, the seals and gaskets may degrade, leading to fluid leaks and possible internal damage.

Regular maintenance, including appropriate fluid changes and timely replacement of worn components, can significantly prolong the life of a S5-47 transmission and avert many of these issues.

When encountering any of these symptoms, it is advisable to consult with a professional mechanic or transmission specialist to diagnose and address the problem before it leads to a complete transmission failure.

Rebuild, Replace, Converting to an Allison

Converting to the Allison 1000PK transmission can offer a significant improvement in the performance, durability, and efficiency of a vehicle. Known for its use in a wide range of applications, from light-duty trucks to heavy-duty commercial vehicles, the Allison 1000PK is a trusted choice for many looking to upgrade their transmission system. Below are some key benefits of making the conversion:

Allison transmissions, including the 1000PK series, are renowned for their durability and longevity. They are designed to handle heavy loads and demanding conditions, reducing the likelihood of frequent repairs and breakdowns, which makes the Allison 1000PK a long-lasting solution.

The Allison 1000PK provides superior torque and power handling, allowing for more efficient and safer towing and hauling. Whether you are pulling a large trailer, boat, or other heavy loads, this transmission can help your vehicle perform at its best under strenuous conditions.

With its sophisticated control system and efficient design, the Allison 1000PK can contribute to better fuel economy. By optimizing shift points based on load, speed, and other factors, it helps the engine run in the most efficient range, potentially saving fuel over time.

The robust design and high-quality components used in the Allison 1000PK often result in lower maintenance costs over time. Its proven durability under various conditions can lead to fewer required repairs and service intervals, translating to long-term cost savings.

The Allison 1000PK is designed to be compatible with a wide range of vehicles and applications. This makes it a versatile option for those looking to upgrade their transmission in various types of vehicles, from light trucks to commercial applications.

Installing a well-regarded and reliable transmission like the Allison 1000PK can increase the resale value of your vehicle. Buyers often appreciate the quality and dependability associated with Allison transmissions, which can make your vehicle more attractive on the resale market.

We provide everything you will need to get the swap done right

- Kit Includes

Allison 1000PK Transmission

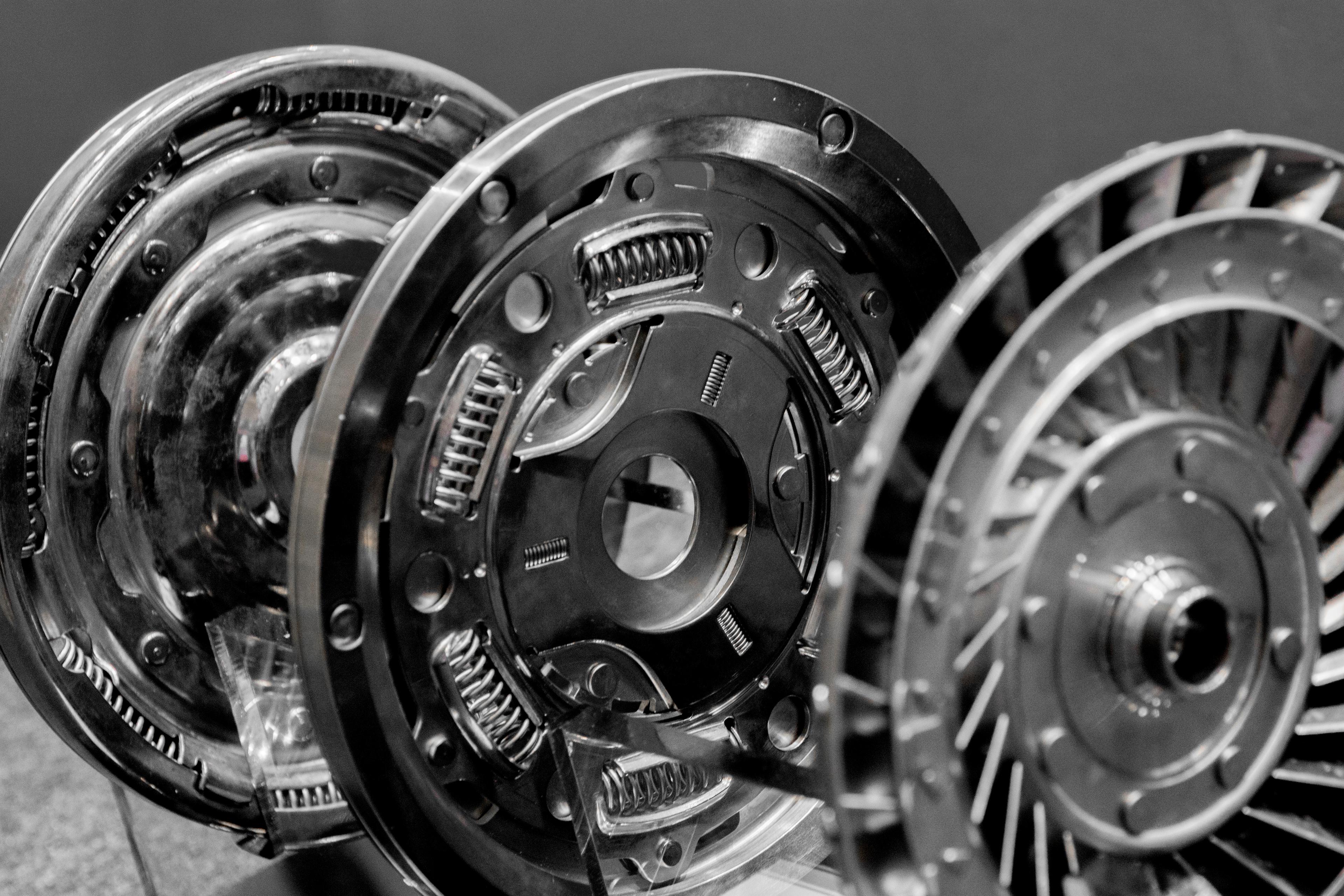

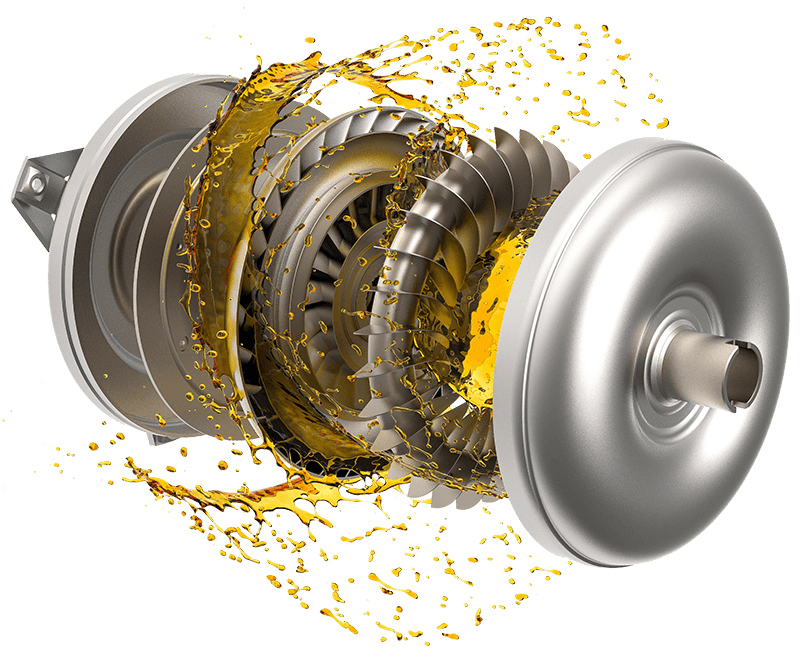

Torque Converter to fit your needs

Wiring Harness

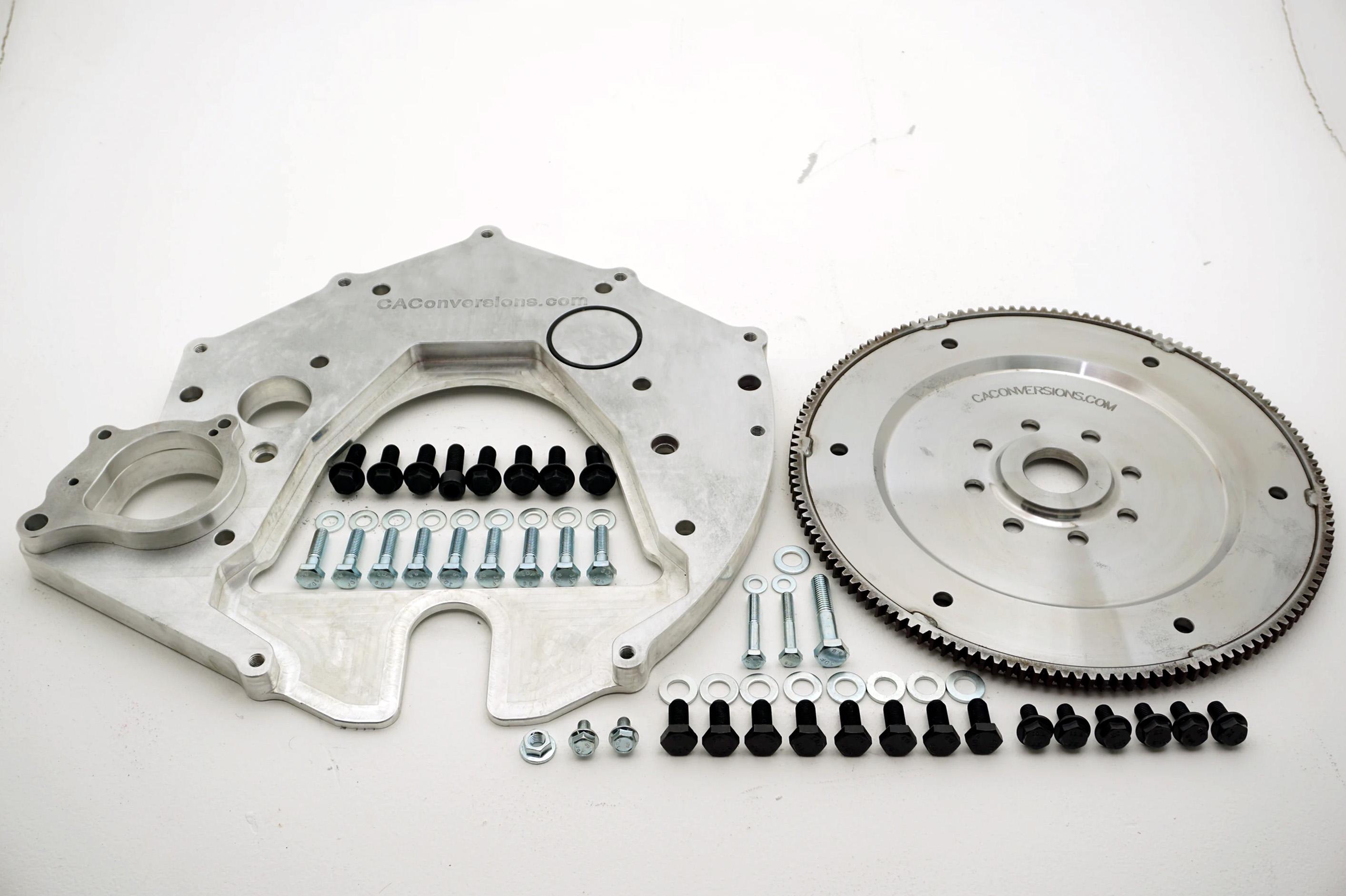

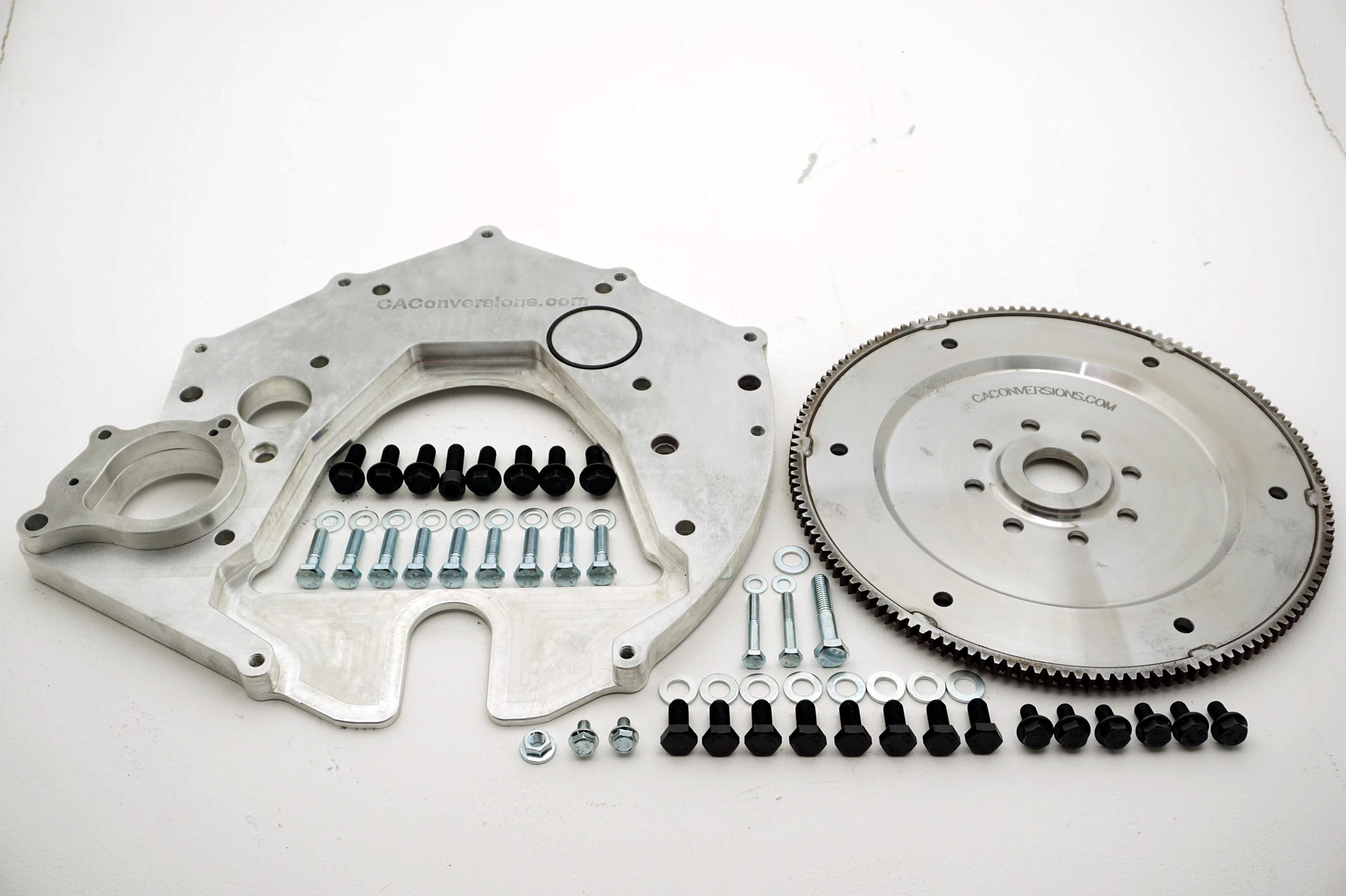

Flex Plate Adapter

Transfer Case Adapter, Couplers, and Tone Rings

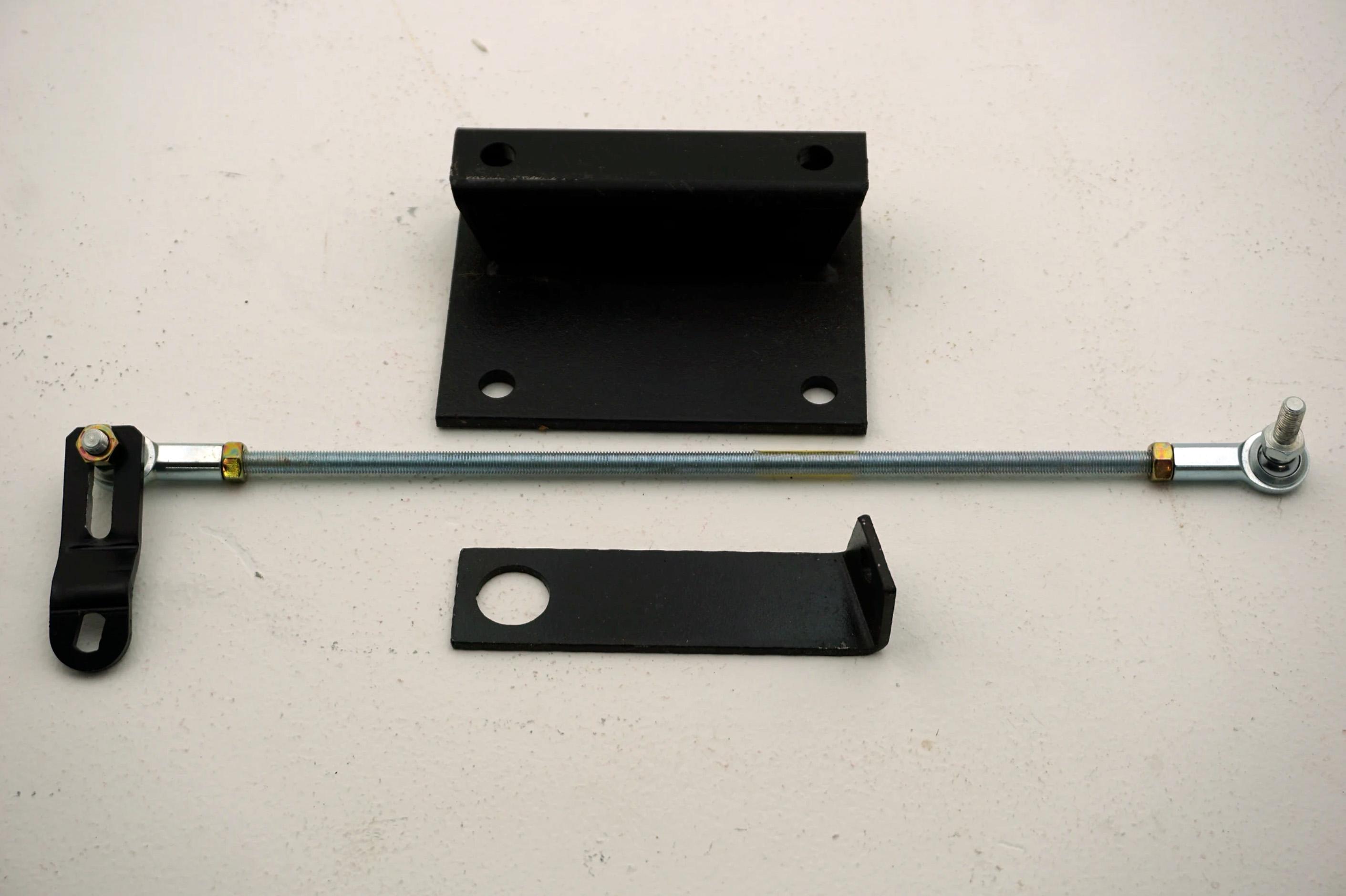

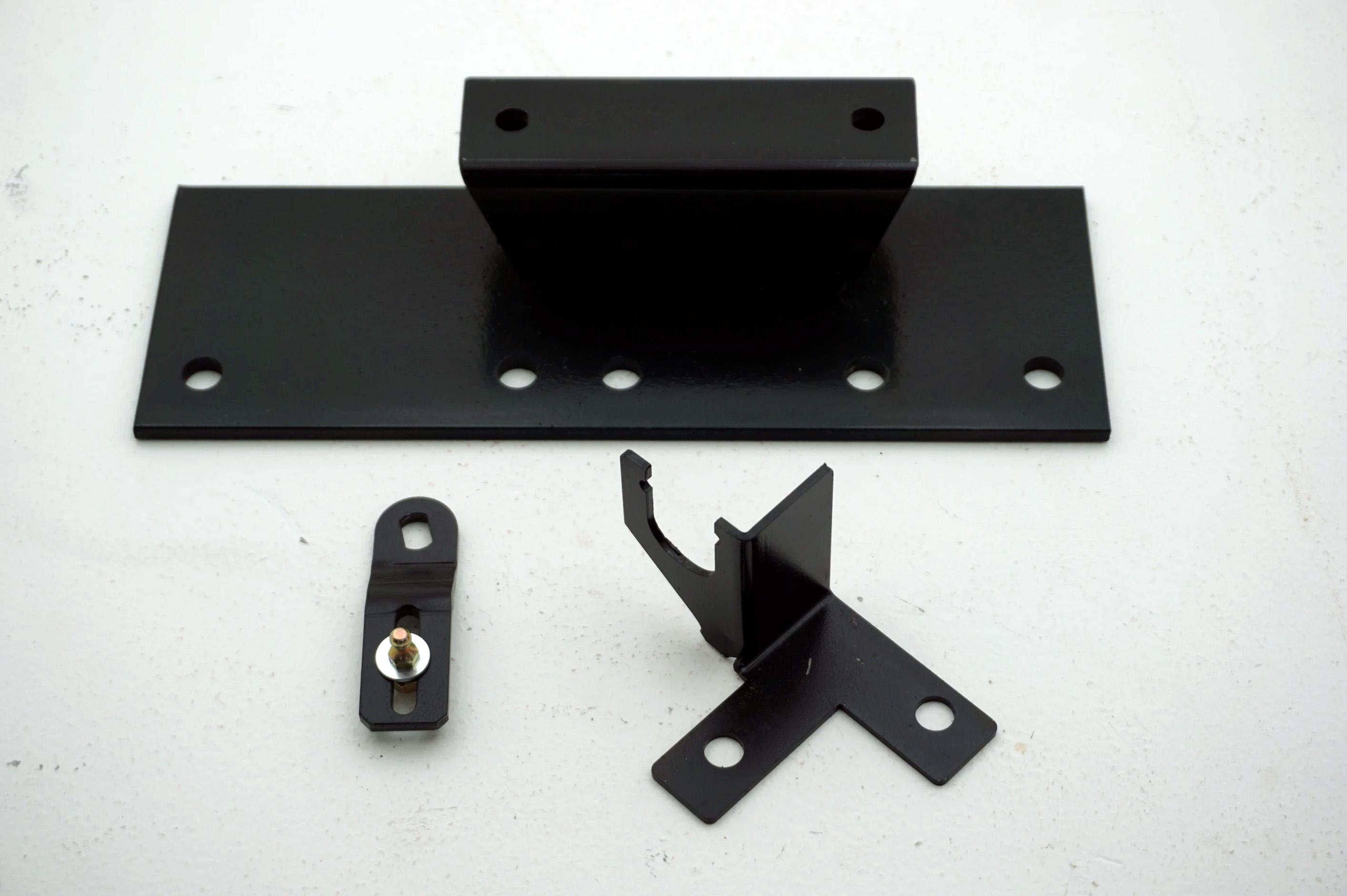

Mounting Kit and Shift Linkage

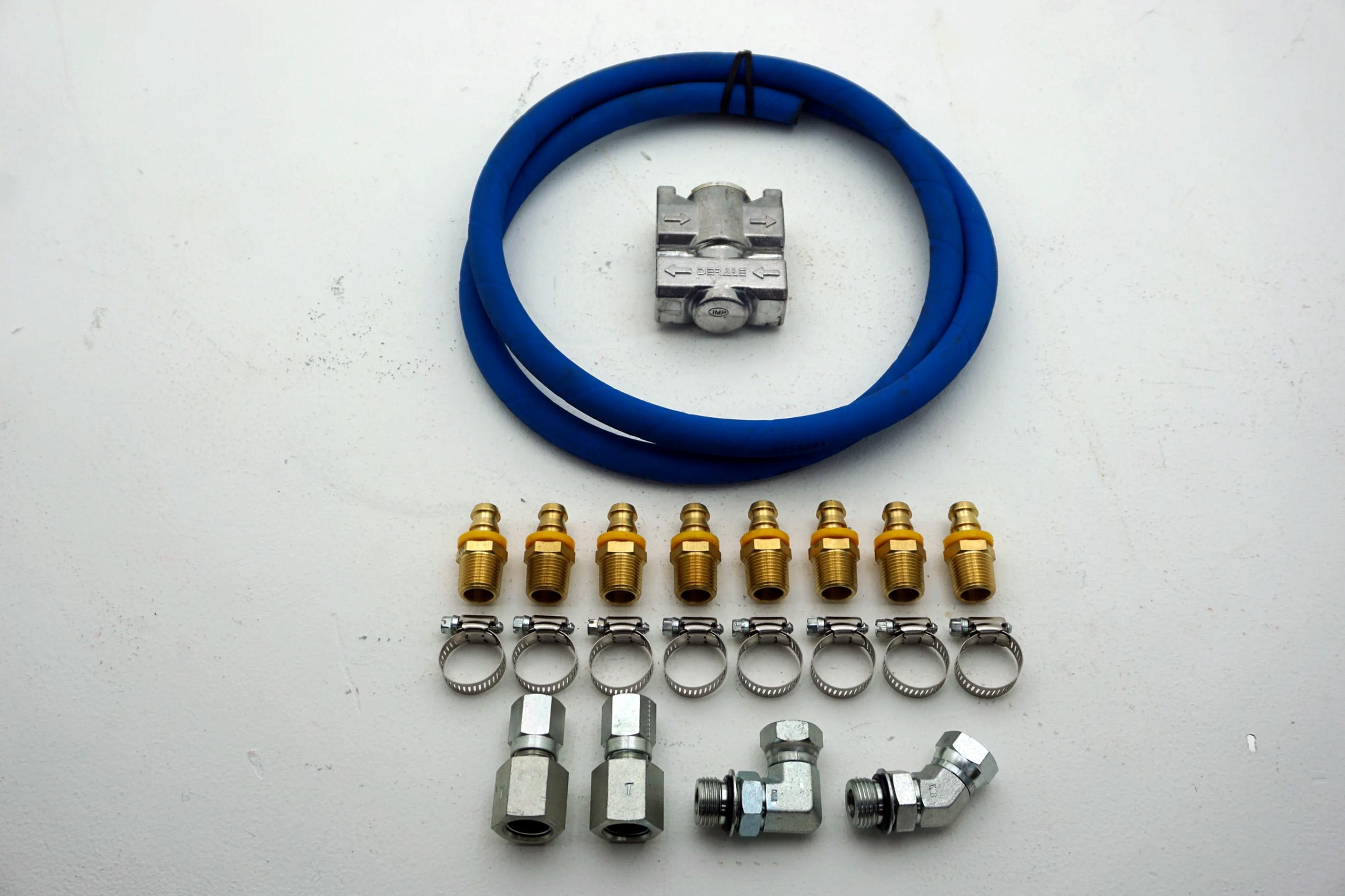

Cooling Kit

CAC Digital Display

Allison Total Control Module (TCM)

CAC Total Control Module (TCM)

How to determine the Right Torque Converter

Maximizing Performance: Using Tire Diameter and Gear Ratio Calculations to Choose the Ideal Torque Converter

FAQ'S

What benefits can I expect from converting my Ford's current transmission to an Allison?

By converting your Ford's transmission to an Allison, you can expect improved durability, enhanced towing capability, better fuel efficiency, and smoother shifts, overall optimizing your vehicle's performance.

Are all Ford vehicles compatible with Allison transmission conversions?

While many Ford vehicles can benefit from an Allison transmission conversion, it's best to consult with a specialist to ensure your specific model's compatibility.

Can I use my existing Ford transfer case with an Allison conversion?

Yes, with our t-case adapters, you can use your existing Ford transfer case in an Allison conversion.

What types of Allison transmissions are best suited for Ford vehicles?

The Allison 1000 series is a popular choice for Ford vehicles due to its reliability and performance. However, the best choice depends on your specific needs and vehicle model.

What's the process involved in converting my Ford's transmission to an Allison?

The conversion process involves removing your Ford's current transmission, fitting the Allison transmission with the necessary adapters, and installing it. The wiring harness, TCM, and other components are also adjusted accordingly.

Will my vehicle's performance and fuel efficiency improve after an Allison transmission conversion?

Yes, an Allison transmission is designed to provide smoother shifts, greater durability, and improved fuel efficiency, all contributing to enhanced vehicle performance.

What specific components are included in the Allison conversion kit for Ford vehicles?

An Allison conversion kit typically includes components such as the transmission (if chosen), TCM, torque converter, wiring harness, adapters, and other necessary parts for the conversion.

Do I need to provide my own Allison transmission for the conversion, or can it be included in the kit?

You can choose to provide your own Allison transmission, or you can opt to include it with your conversion kit purchase.

Can I convert my Ford's transmission myself, or should I hire a professional?

While it's possible for experienced individuals to perform the conversion, it's generally recommended to seek professional help to ensure the job is done correctly and safely.

How long does a typical Allison conversion take for a Ford vehicle?

The conversion time can vary greatly depending on the vehicle and the specific conversion kit. On average, it might take a few days to complete.

Will an Allison conversion affect my Ford vehicle's warranty?

An Allison conversion may affect your vehicle's warranty depending on the terms and conditions of your specific warranty agreement. We recommend checking with your warranty provider before proceeding with the conversion.

What should I do if I face issues after converting my Ford's transmission to an Allison?

Should you encounter any problems post-conversion, we recommend contacting your conversion specialist for troubleshooting advice or potential service needs.

Can I use an Allison transmission from another vehicle (like a Chevrolet/GM) for my Ford conversion?

Yes, an Allison transmission from another vehicle can be used, provided it's compatible with your Ford model. Ensure to consult with your conversion specialist before proceeding.

Do you offer rebuilding services for Allison transmissions?

Yes, we provide rebuilding services for Allison transmissions, ensuring your transmission operates at peak performance.

What is the cost range for an Allison transmission conversion for Ford vehicles?

The cost can vary significantly depending on the specific Allison model, whether you're providing the transmission or purchasing it as part of the kit, and any additional services required. Please contact us directly for a more accurate estimate.

Financing Available

Financing is available, so that you can get on the road faster