Dodge 68RFE Transmission

Convert your Dodge 68RFE to an Allison

Transform Your Drive: Making the Switch to an Allison 1000PK Transmission

Configure your truckUpgrade your ride with a transformative conversion from a Dodge 68RFE to an Allison 1000PK transmission. Renowned for its exceptional strength, smooth operation, and unbeatable durability, the Allison 1000PK offers unparalleled performance that leaves the 68RFE in its wake. Whether you're hauling heavy loads, embarking on a cross-country journey, or demanding optimal control and response from your vehicle, this conversion promises enhanced efficiency, reduced maintenance costs, and a driving experience that’s second to none. Make the switch today and empower your Dodge with the gold standard of transmissions—the Allison 1000PK.

Overview of the 68RFE Transmission

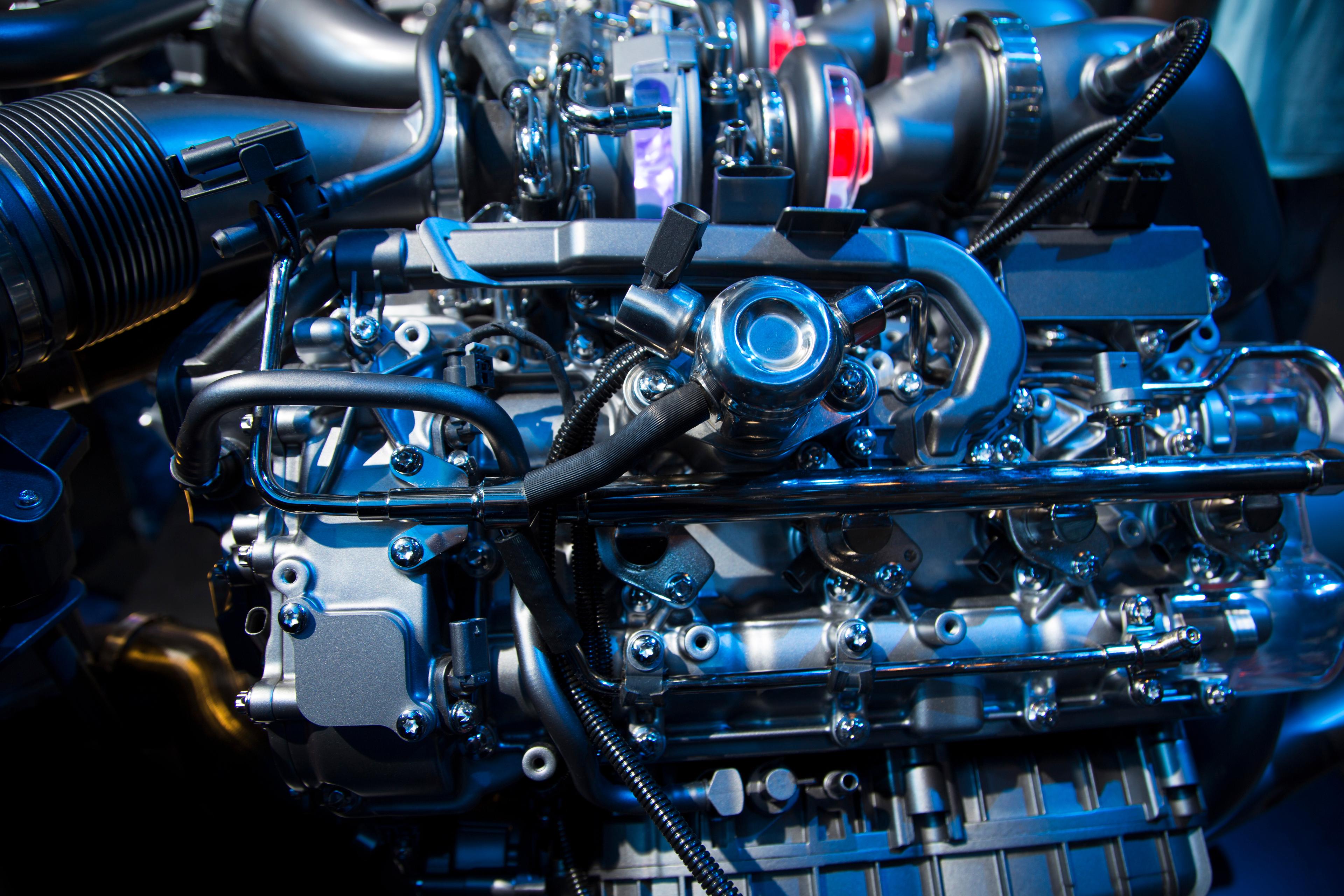

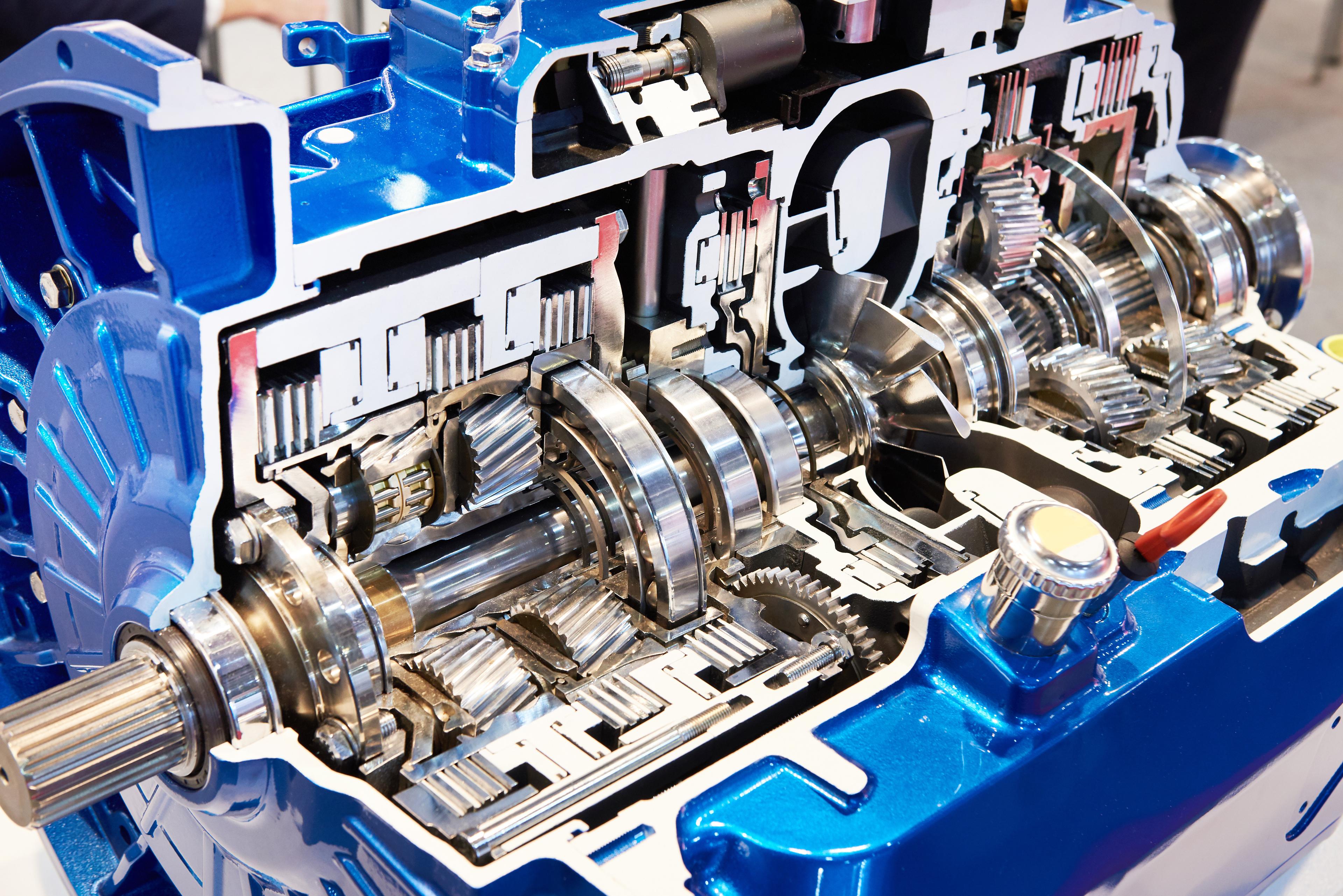

The 68RFE is a six-speed automatic transmission designed and manufactured by Chrysler, introduced in the late 2000s to pair primarily with Dodge Ram 2500 and 3500 series trucks equipped with the formidable Cummins turbodiesel engine. Engineered for durability and strength, the 68RFE has gained a reputation among truck owners for its capability to handle substantial towing and hauling demands. Its fully electronic operation allows for adaptive learning and shift control, aimed at optimizing shift quality and ensuring long-term reliability.

Its six forward gears, including a double overdrive, enable a broad range of gear ratios for optimal power and fuel efficiency across a wide array of driving conditions. Constructed with a robust steel case and utilizing a multi-plate clutch design, the 68RFE is designed to withstand considerable abuse, making it well-suited for heavy-duty applications. Its smart electronic controls adjust and refine shift points based on driving conditions, allowing for both comfortable cruising and responsive, high-torque shifting when necessary.

As automatic transmissions have become the norm in modern trucks due to their convenience and efficiency, the 68RFE serves as a testament to this trend. It is designed for the driver who seeks the combination of heavy-duty capability without sacrificing the comfort and ease of an automatic transmission. For those who require a dependable, hardworking transmission that can tackle heavy loads and tough tasks without frequent intervention, the 68RFE remains a strong and reliable choice.

68RFE Features

The 68RFE transmission is a heavy-duty staple in Dodge Ram trucks, known for its blend of performance and durability. Here are some key features that make the 68RFE stand out:

- High Torque Capacity: Engineered for heavy-duty applications, the 68RFE is designed to handle high levels of torque, ideal for towing and hauling substantial loads.

- Adaptive Learning and Shift Control: Advanced electronic controls allow the 68RFE to adapt to varying driving conditions and optimize shift points for performance, comfort, and fuel economy.

- Durable Construction: The 68RFE is built to last, featuring a rugged steel case and multi-plate clutch design for durability and longevity under heavy-duty use.

- Wide Gear Ratio Spread: With six forward gears, including a double overdrive, the 68RFE offers an extensive range of gear ratios, balancing powerful low-end performance with fuel-efficient cruising.

- Integrated Electronic Controls: This feature ensures optimal and consistent shift quality, adapting to driver input and external conditions to maximize efficiency and reliability.

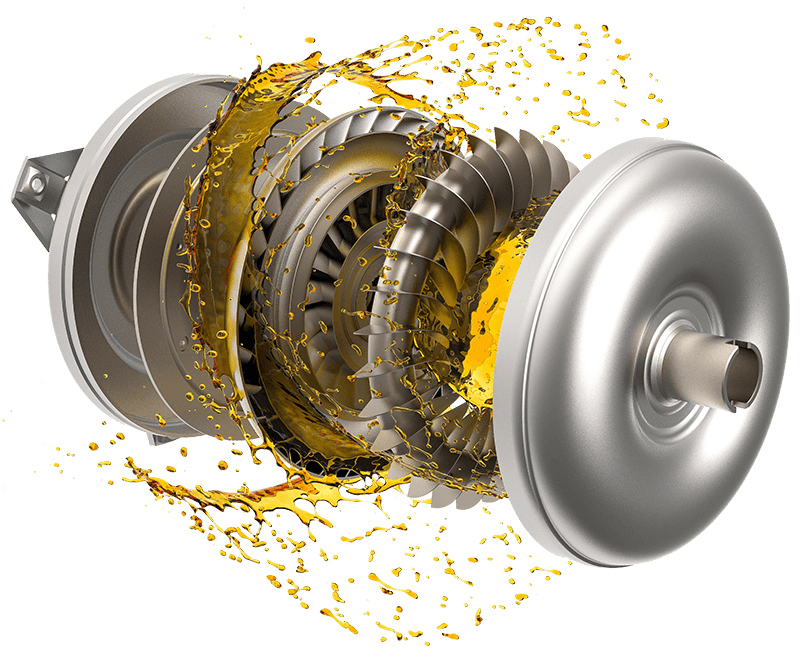

- Torque Converter Clutch: A torque converter clutch system allows for a direct engine-to-transmission linkage under certain conditions, improving efficiency and reducing heat.

- Lock-Up Capability: The 68RFE offers lock-up in multiple gears, further enhancing fuel economy and cooling efficiency.

In summary, the 68RFE is a robust, reliable, and technologically advanced automatic transmission designed to meet the rigorous demands of heavy-duty truck applications. Its features are meticulously engineered to offer drivers a harmonious blend of control, substantial towing capacity, and steadfast performance under a multitude of conditions.

68RFE Common Issues and Signs of Failures

While the 68RFE transmission is designed for durability and robust performance, like all mechanical components, it can have its issues. Here are some common problems associated with the 68RFE transmission, along with signs that it might be failing:

- Overheating: One of the main issues with the 68RFE is overheating, especially under heavy loads. This can lead to premature wear of components and potential failure. Installing an auxiliary transmission cooler is often recommended.

- Solenoid Failures: The 68RFE’s solenoids can fail, resulting in erratic shifting or loss of gears. This usually triggers a check engine light and requires replacement of the solenoid pack.

- Worn Clutch Packs: Under heavy loads, the clutch packs can wear prematurely, resulting in slipping gears and eventual transmission failure.

- Valve Body Issues: Problems with the valve body can lead to irregular shifts, delayed shifting, or harsh shifts. Reconditioning or replacing the valve body is a common solution.

Regular maintenance, including timely fluid and filter changes with appropriate transmission fluid, can significantly extend the life of a 68RFE transmission and prevent many of these issues. When experiencing any of these symptoms, it is advisable to consult with a professional mechanic or transmission specialist to diagnose and address the problem before it results in a complete transmission failure.

Rebuild, Replace, Converting to an Allison

Converting from a Dodge 68RFE manual transmission to an Allison 1000PK automatic transmission can bring several benefits, depending on the specific needs and use of the vehicle. Here are some notable advantages of making such a conversion.

The Allison 1000 series is known for its robust construction and long service life, making it a popular choice among heavy-duty truck owners who need a transmission that can withstand severe duty cycles without frequent breakdowns.

The Allison 1000PK is designed for heavy-duty applications and can significantly increase a vehicle’s towing and payload capacities. This is perfect for those who regularly tow heavy trailers or haul substantial loads.

The Allison 1000PK is engineered for smooth and precise shifting. Its advanced control system constantly adapts to changes in the vehicle’s operating conditions, resulting in consistently seamless and efficient shifting.

The Allison 1000PK is designed for optimal fuel economy, particularly under heavy-load conditions. Its precise and adaptive shift strategies can help to reduce fuel consumption, which is a significant benefit for long-haul or frequent drivers.

For those with powerful diesel or modified engines, the Allison 1000PK is designed to handle high torque outputs, making it an excellent match for such setups without risking premature wear or failure.

The Allison 1000PK comes with advanced features, such as adaptive learning capabilities that adjust shift patterns based on the driver’s behavior and operating conditions, enhancing the driving experience.

Automatic transmissions can help reduce wear on associated drivetrain components, as the computer-controlled shifts can be more consistent and less stressful on the equipment than manual shifting.

An Allison transmission is often seen as a premium upgrade, which can increase the resale value of the vehicle. Prospective buyers may be willing to pay more for a vehicle with a reliable and well-regarded transmission.

Allison transmissions are supported by a comprehensive global service network. This means that, no matter where you are, you're likely to find a qualified service technician who is familiar with your transmission.

The Allison 1000PK allows for a degree of customization in its operation, letting drivers or fleet managers tailor the transmission’s behavior to suit specific needs or preferences, which is especially useful for commercial applications.

Allison transmissions are designed to be relatively easy to service, with extended fluid change intervals and clear service protocols. This can lead to lower maintenance costs over the life of the transmission.

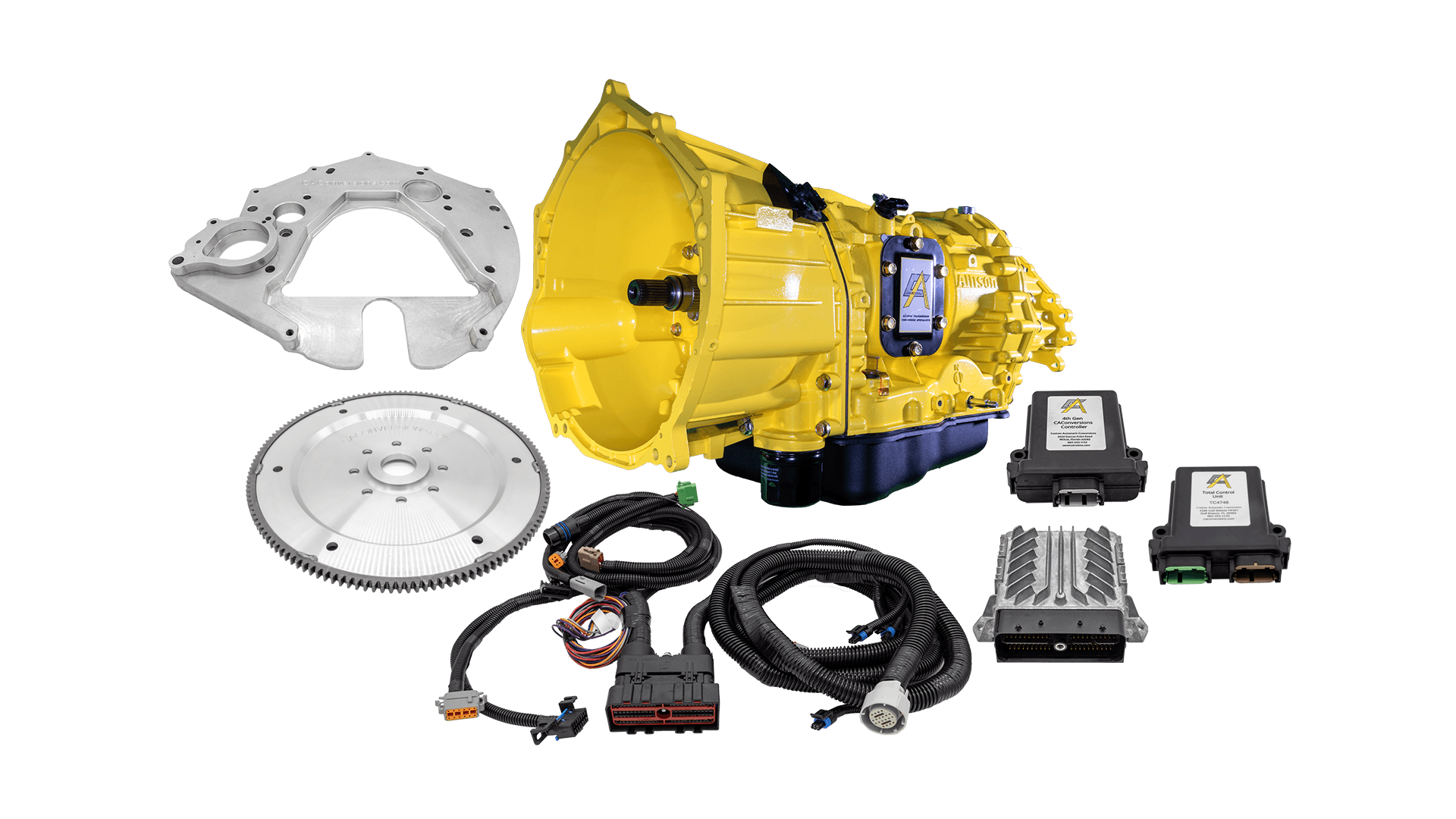

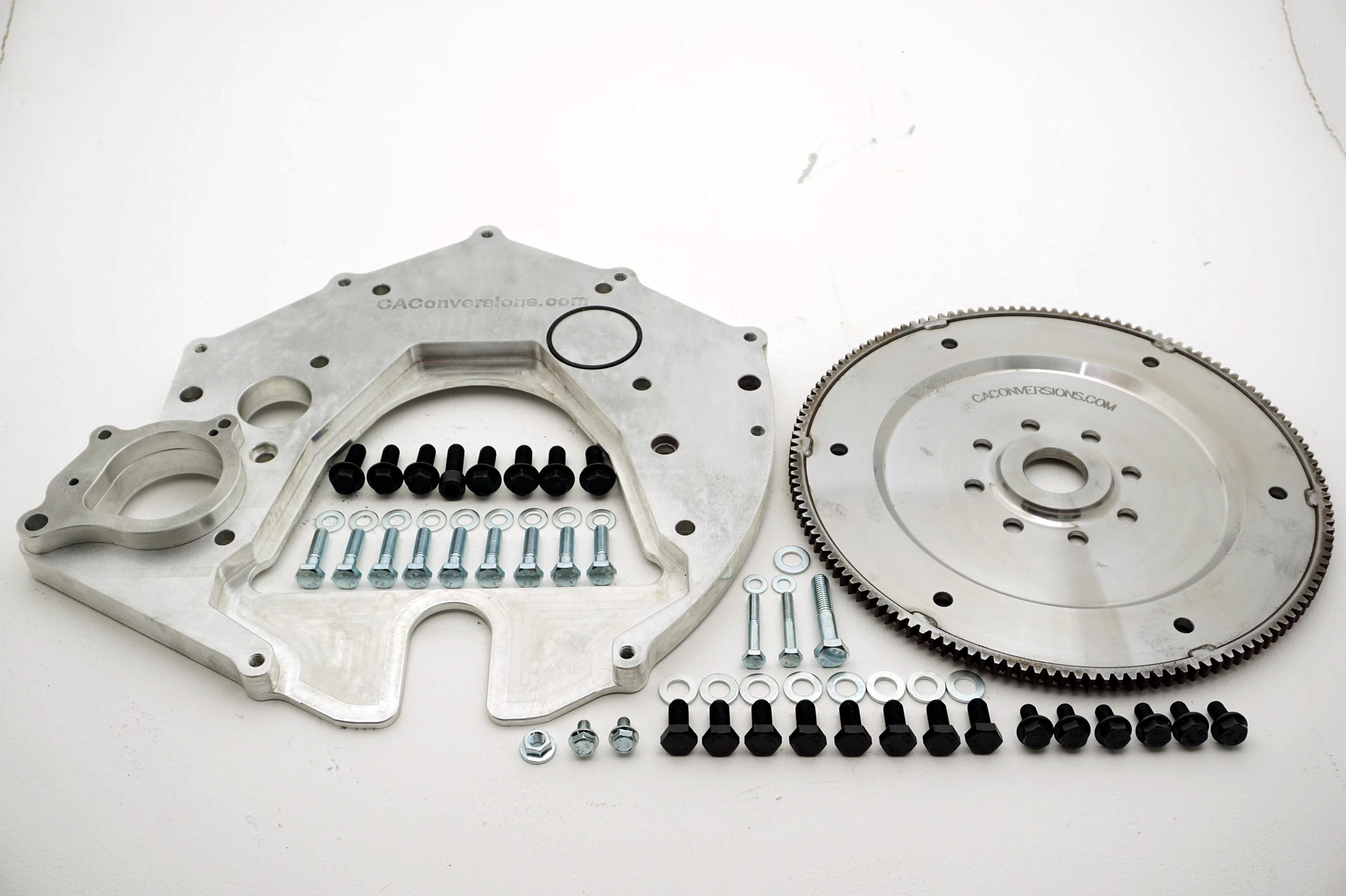

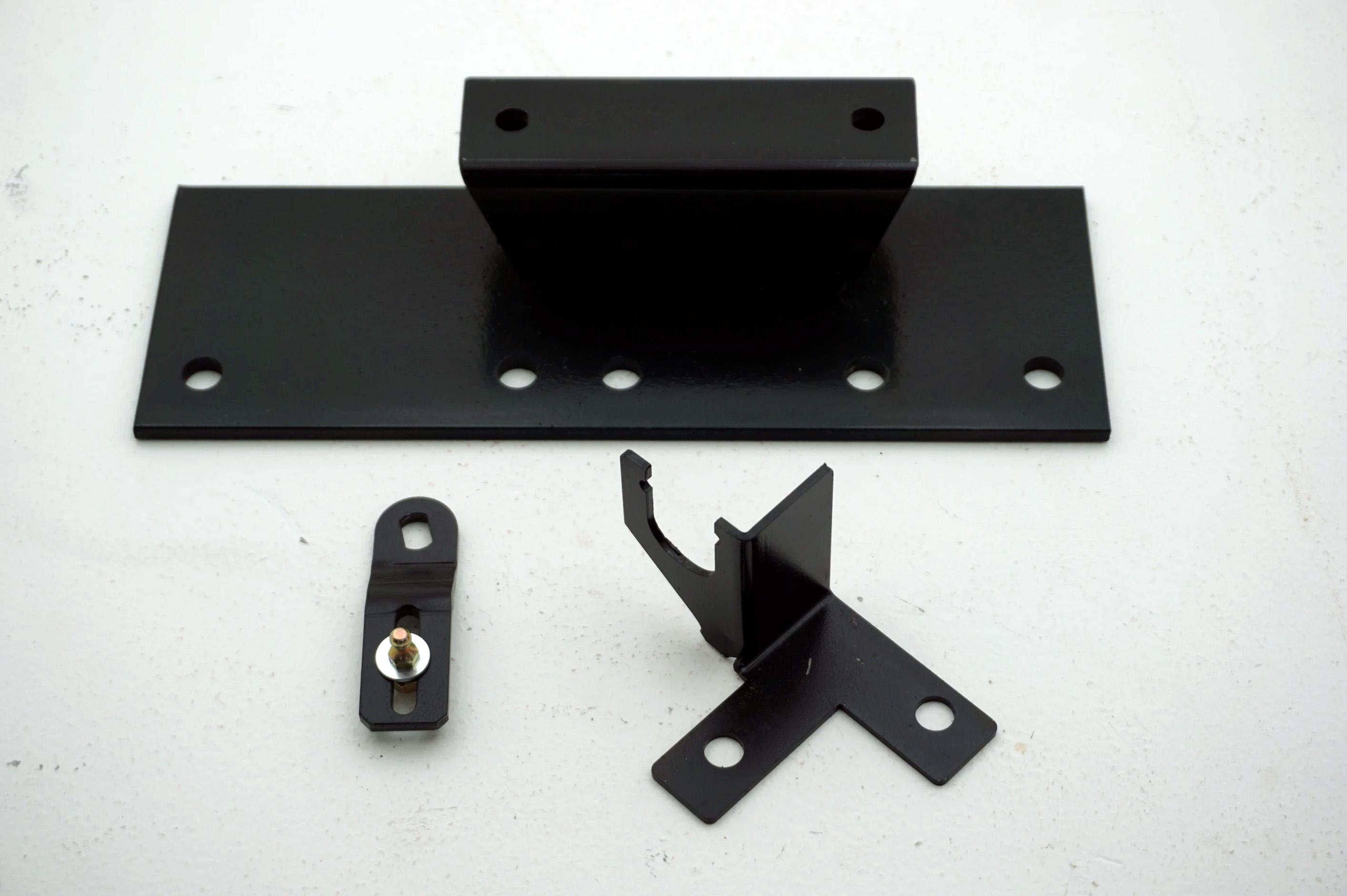

We provide everything you will need to get the swap done right

- Kit Includes

Allison 1000PK Transmission

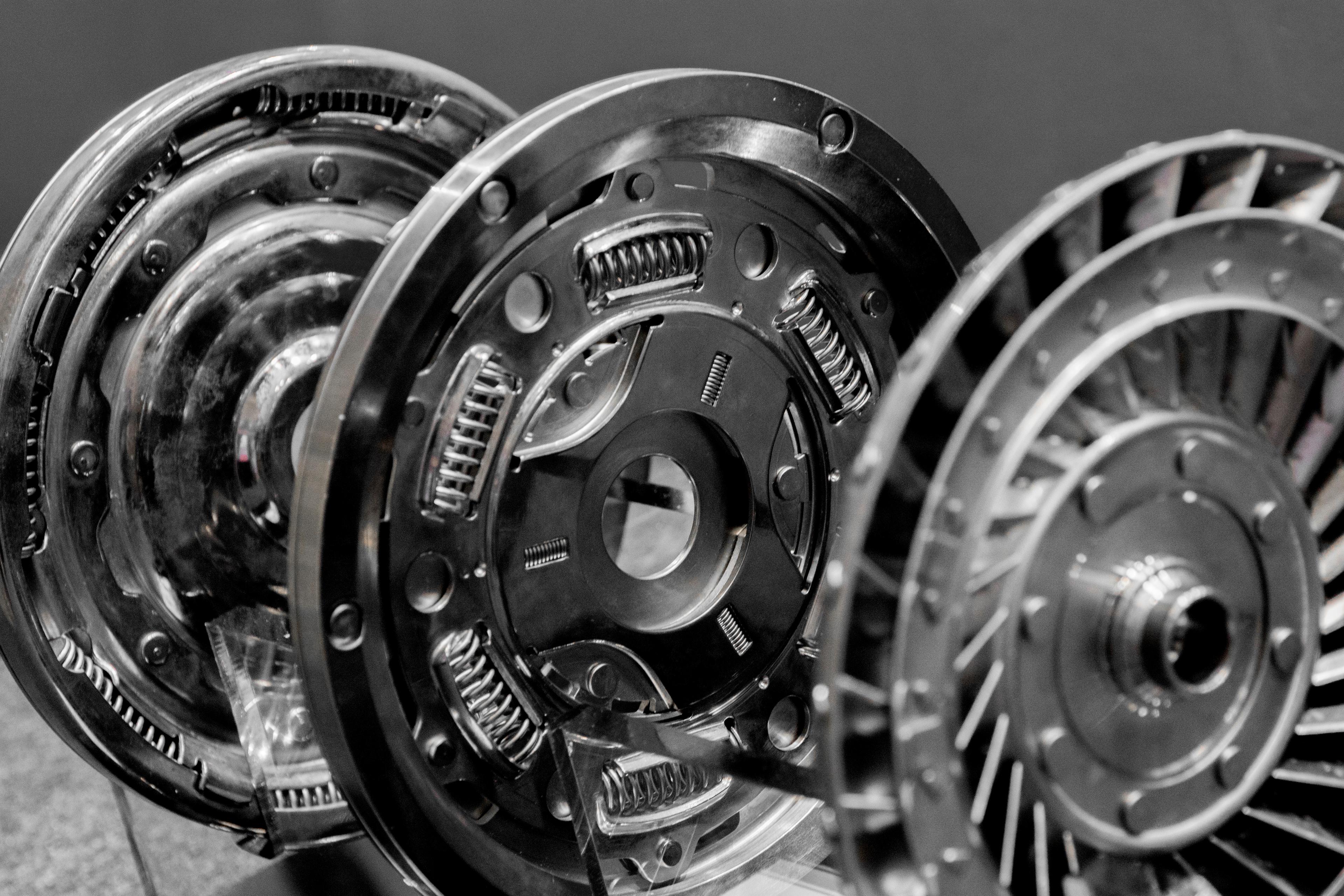

Torque Converter to fit your needs

Wiring Harness

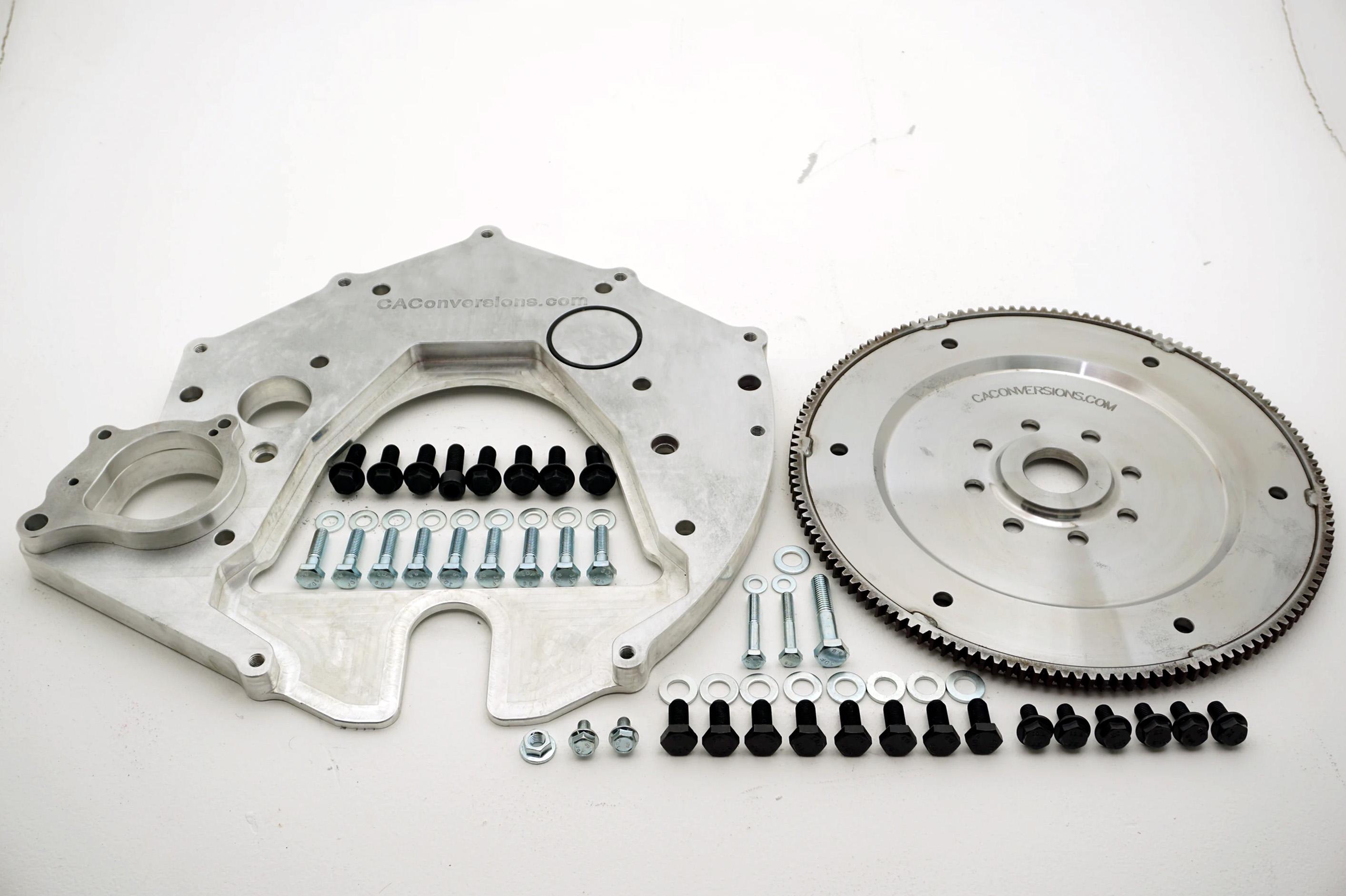

Flex Plate Adapter

Transfer Case Adapter, Couplers, and Tone Rings

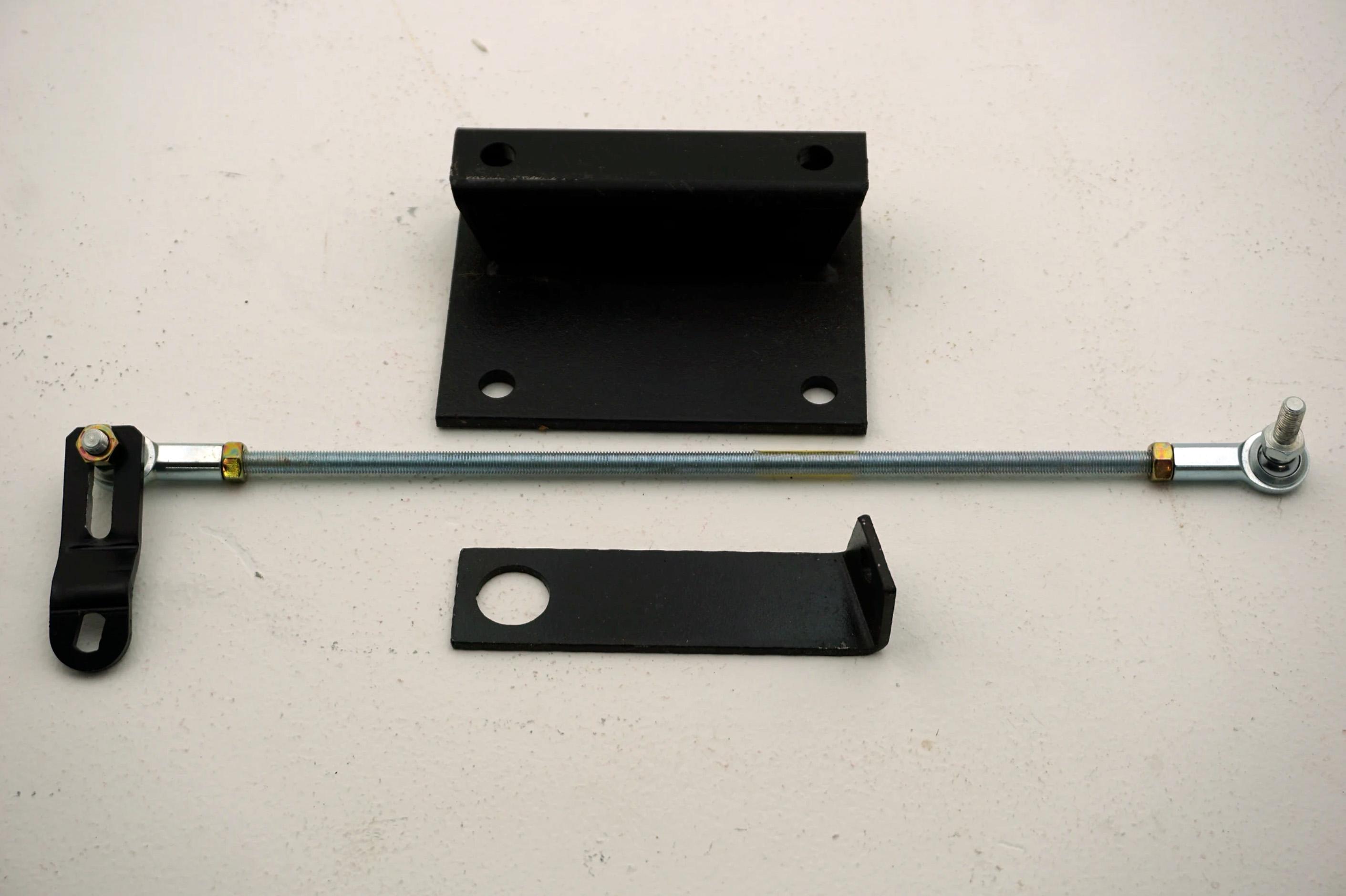

Mounting Kit and Shift Linkage

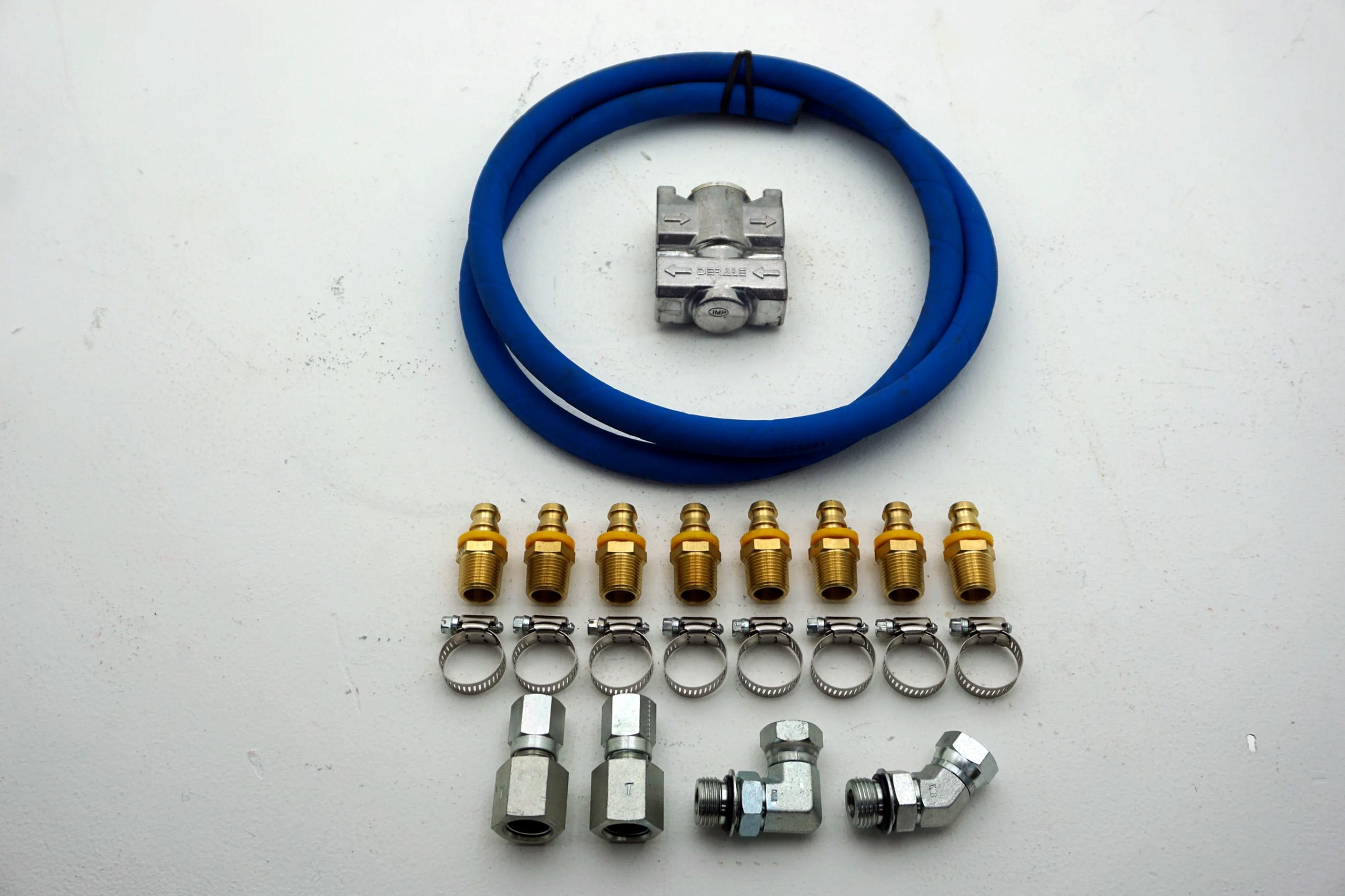

Cooling Kit

CAC Digital Display

Allison Total Control Module (TCM)

CAC Total Control Module (TCM)

68RFE Allison Conversion Kits

How to determine the Right Torque Converter

Maximizing Performance: Using Tire Diameter and Gear Ratio Calculations to Choose the Ideal Torque Converter

FAQ'S

What are the benefits of converting my Dodge Ram's current transmission to an Allison?

Converting your Dodge Ram's transmission to an Allison can result in numerous benefits including improved durability, enhanced towing capability, increased fuel efficiency, and smoother gear shifts, thus optimizing your vehicle's performance.

Is an Allison conversion compatible with all Dodge Ram models?

Most Dodge Ram models can benefit from an Allison transmission conversion, but it's advisable to consult with a specialist to ensure compatibility with your specific model.

Can I use my existing Dodge Ram transfer case with an Allison conversion?

Yes, with the right adapters, your existing Dodge Ram transfer case can be utilized in an Allison conversion.

Which Allison transmissions are best suited for Dodge Ram vehicles?

The Allison 1000 series is a popular choice for Dodge Ram vehicles due to its reliability and performance, but the best option depends on your particular needs and vehicle model.

What is the process for converting my Dodge Ram's transmission to an Allison?

The conversion process involves removing your Dodge Ram's current transmission, fitting the Allison transmission with the necessary adapters, and installing it. The wiring harness, TCM, and other components are also adjusted accordingly.

Will my Dodge Ram's performance and fuel economy improve with an Allison transmission conversion?

Yes, an Allison transmission is designed to provide smoother shifts, increased durability, and better fuel efficiency, all of which contribute to improved vehicle performance.

What specific components come with the Allison conversion kit for Dodge Ram vehicles?

An Allison conversion kit typically includes components such as the transmission (if chosen), TCM, torque converter, wiring harness, adapters, and other necessary parts for the conversion.

Can I provide my own Allison transmission for the conversion, or can it be included in the kit?

You have the option to either provide your own Allison transmission or include it with your conversion kit purchase.

Can I perform the Allison transmission conversion myself, or do I need a professional?

While it's possible for experienced individuals to do the conversion, it's generally recommended to hire a professional to ensure the job is done correctly and safely.

How long does a typical Allison conversion take for a Dodge Ram?

The conversion time can vary based on the vehicle and the specific conversion kit. On average, it might take a few days to complete.

Will converting my Dodge Ram's transmission to an Allison affect my warranty?

An Allison conversion could affect your vehicle's warranty depending on the specific terms of your warranty agreement. We recommend checking with your warranty provider before proceeding with the conversion.

What should I do if I encounter issues after converting my Dodge Ram's transmission to an Allison?

If you face any problems after the conversion, it's best to contact your conversion specialist for troubleshooting assistance or potential service needs.

Can I use an Allison transmission from a different vehicle (like a Chevrolet/GM) for my Dodge Ram conversion?

Yes, an Allison transmission from another vehicle can be used, provided it's compatible with your Dodge Ram model. Ensure to consult with your conversion specialist before proceeding.

Do you offer rebuilding services for Allison transmissions?

Yes, we do offer rebuilding services for Allison transmissions, ensuring your transmission is operating at peak performance.

What is the cost range for an Allison transmission conversion for Dodge Ram vehicles?

The cost can vary significantly depending on the specific Allison model, whether you're providing the transmission or purchasing it as part of the kit, and any additional services required. Please contact us directly for a more precise estimate.

Financing Available

Financing is available, so that you can get on the road faster